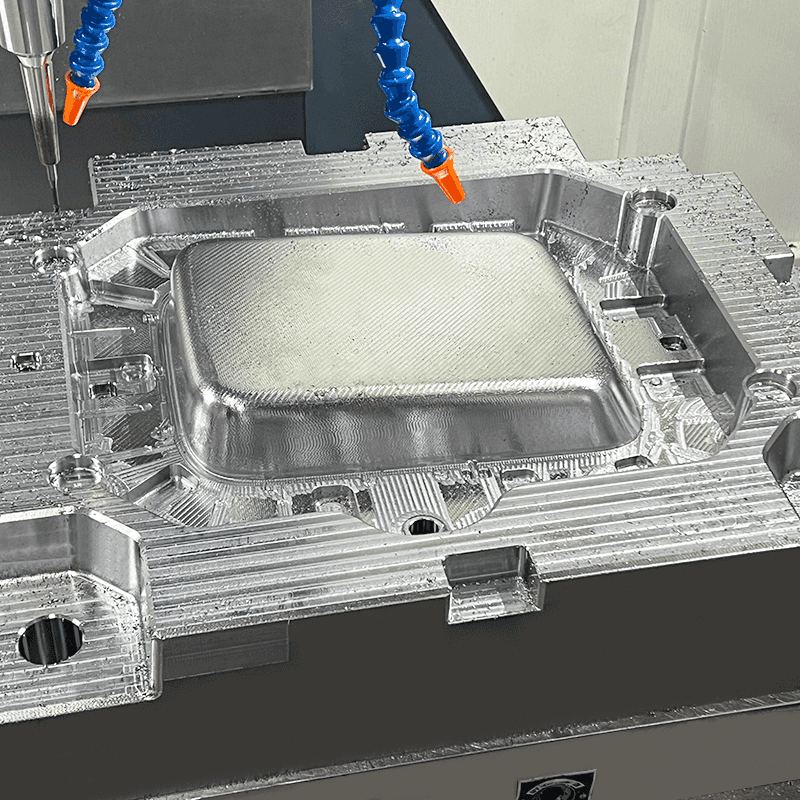

Custom Automotive Parts Mold

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

51 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

Custom automotive parts molds are essential in the manufacturing of high-quality automotive components. At our company, we specialize in composite molds and injection molds, offering tailored solutions to meet the unique needs of our customers.

1. Comprehensive Overview

Our custom automotive parts molds are designed to meet the rigorous demands of the automotive industry. These molds are crucial for producing parts with precise specifications, ensuring durability and performance in vehicles. We utilize advanced technologies and expertise in both composite and injection molding processes to deliver molds that exceed industry standards.

2. Composite Molds

Composite molds are known for their ability to produce lightweight yet strong automotive components. Our composite molds feature:

Material Versatility: We use high-quality composite materials such as fiberglass and carbon fiber to create molds that are both durable and lightweight. These materials offer nice resistance to heat and corrosion, making them ideal for automotive applications.

Precision Engineering: Our composite molds are crafted with precision to ensure accurate replication of automotive parts. This precision is essential for achieving the desired fit and functionality of components in vehicles.

Customizable Solutions: We provide customizable composite molds to meet specific requirements of our clients. Whether it’s for a unique part design or specialized application, our molds can be tailored to suit various needs.

3. Injection Molds

Injection molds are integral for high-volume production of automotive parts. Our injection molds offer:

High Efficiency: Injection molding is known for its efficiency in producing large quantities of parts quickly and with consistent quality. Our molds are designed to maximize production efficiency while maintaining high standards of quality.

Complex Geometry: Our injection molds can accommodate complex part geometries, allowing us to create intricate automotive components with ease. This capability is essential for producing parts with complex shapes and features.

Material Compatibility: We work with a wide range of materials, including plastics and metals, to meet the diverse needs of automotive manufacturing. Our injection molds are engineered to handle different material types, ensuring versatility in production.

4. One-off Solutions

We are capable of providing one-off solutions for our customers, which includes:

Prototype Development: For clients needing prototypes or small production runs, our custom molds can be designed and produced quickly to validate designs before full-scale production.

Custom Design: Each mold is designed based on specific requirements, ensuring that it meets the exact specifications and standards of the automotive part being produced.

Rapid Turnaround: Our expertise and advanced technology allow us to deliver custom molds within a short timeframe, providing quick solutions for urgent or specialized needs.

5. Quality Assurance

Quality is at the core of our mold manufacturing process. We adhere to strict quality control measures to ensure that each mold meets high standards:

Rigorous Testing: Each mold undergoes thorough testing to ensure it performs reliably under production conditions. This testing includes stress testing, dimensional accuracy checks, and performance evaluations.

Durability and Longevity: Our molds are built to last, with materials and construction techniques that ensure durability and longevity. This reliability translates into consistent performance and reduced downtime in production.

Customer Feedback: We actively seek feedback from our clients to continuously improve our molds and services. This commitment to customer satisfaction helps us deliver products that meet and exceed expectations.