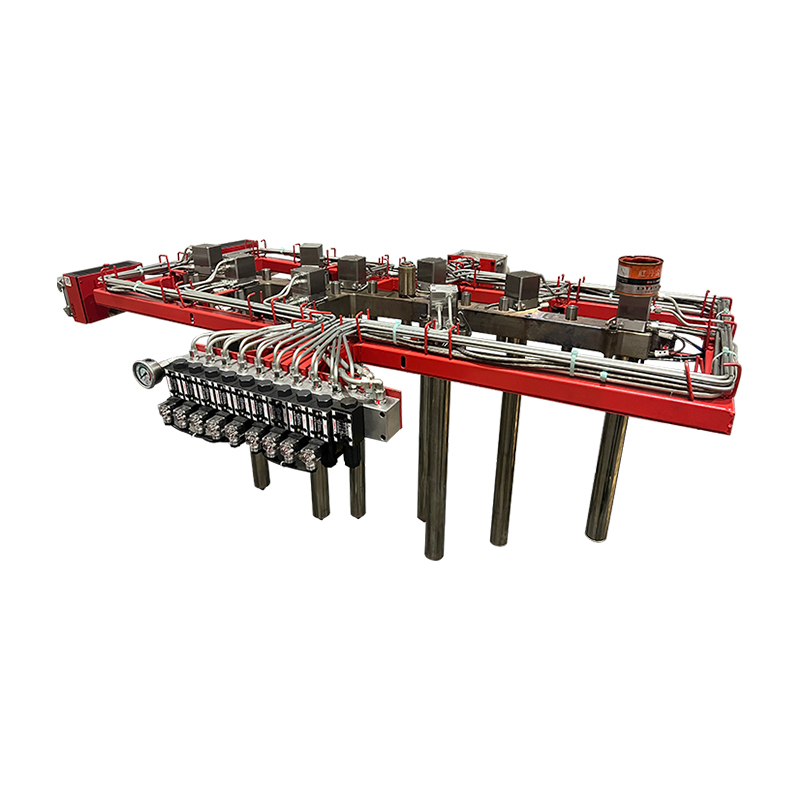

Automotive Hot Runner System Mold

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

55 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The Automotive Hot Runner System Mold is a sophisticated tool designed for the injection molding of automotive parts. It utilizes a hot runner system, which keeps the plastic material molten and at a consistent temperature as it moves through the mold. This approach significantly reduces cycle times and improves the overall efficiency of the molding process.

Purpose and Application: This mold is specifically engineered to produce high-precision components for various automotive applications, including dashboards, trim panels, and engine parts. Its design accommodates the complex geometries and stringent quality requirements typical of automotive manufacturing.

1. Key Advantages

The Automotive Hot Runner System Mold offers several significant advantages that enhance its performance and suitability for automotive applications:

Reduced Cycle Times: By maintaining a consistent temperature in the runner system, the mold reduces the time needed for each molding cycle. This efficiency translates to higher production rates and lower manufacturing costs.

Consistent Quality: The hot runner system ensures that the plastic material remains at a uniform temperature, to more consistent and high-quality parts. This consistency is crucial for meeting the rigorous standards of the automotive industry.

Minimized Waste: Traditional molding systems often result in substantial plastic waste, especially in the runners and sprues. The hot runner system reduces this waste by keeping the material in a molten state, thus reducing scrap and optimizing material usage.

Enhanced Design Flexibility: The hot runner system allows for greater design freedom and complexity. It supports intricate part designs and multi-cavity molds, making it possible to produce complex automotive components with ease.

Complex Geometries: Automotive parts often require complex shapes and features. The hot runner system facilitates the molding of these intricate designs without compromising on quality or performance.

Multi-Cavity Capability: The mold can be configured with multiple cavities, enabling the production of several parts in a single cycle. This capability is particularly beneficial for high-volume automotive manufacturing.

Improved Energy Efficiency: The hot runner system’s ability to maintain consistent temperatures and reduce cycle times contributes to overall energy savings. This efficiency is not only cost-effective but also environmentally friendly.

Lower Energy Consumption: By optimizing the molding process and reducing waste, the system consumes less energy compared to traditional molding methods.

Reduced Heating Costs: The consistent temperature control reduces the need for excessive heating, further lowering energy costs.

2. Key Features

The Automotive Hot Runner System Mold incorporates several advanced features that contribute to its effectiveness and reliability:

Precision Temperature Control: The mold is equipped with precise temperature control mechanisms that ensure the plastic material remains at the optimal temperature throughout the molding process.

Uniform Heating: Advanced heating elements and temperature sensors maintain a uniform temperature, preventing issues such as cold spots or overheating.

Adjustable Settings: The temperature control system allows for fine-tuning to accommodate different materials and molding requirements.

Robust Construction: The mold is constructed from high-quality, durable materials that can withstand the demanding conditions of automotive manufacturing.

Long Service Life: The robust construction ensures that the mold has a long service life, reducing the need for frequent replacements or repairs.

Resistance to Wear and Tear: High-grade materials and precision engineering contribute to the mold’s resistance to wear and tear, ensuring consistent performance over time.

User-Friendly Design: The mold is designed with ease of use in mind, featuring user-friendly controls and maintenance features.

Ease of Setup: The mold’s design simplifies the setup and calibration process, reducing downtime and increasing operational efficiency.

Maintenance Access: Convenient access points for maintenance and cleaning help to keep the mold in optimal condition and minimize downtime.