Injection Automotive Parts Mold

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

50 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

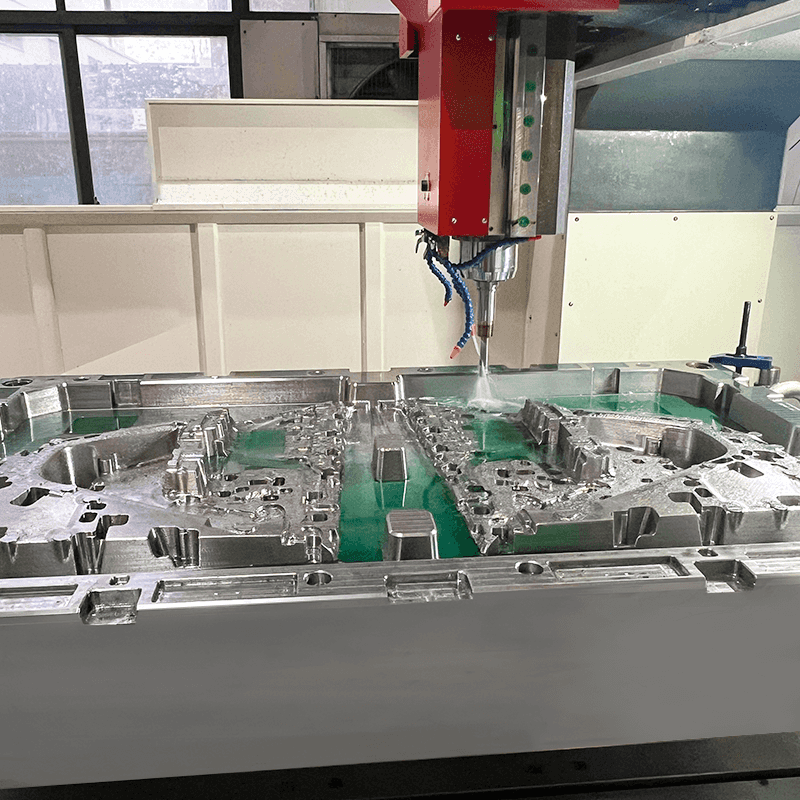

Injection molds are critical components in the production of high-quality automotive parts. The precision and durability of these molds play a significant role in ensuring the performance and longevity of the final products. Our Injection Automotive Parts Mold offers quality and reliability, crafted to meet the stringent demands of the automotive industry.

1. Mould Steel Options:

The choice of mould steel is paramount in the manufacturing of injection molds, as it directly affects the mold's performance, lifespan, and quality of the finished parts. Our molds are manufactured using high-grade steels, including P20, S50C, and S45, each selected for its unique properties:

P20 Steel: Known for its nice hardness and toughness, P20 steel is a pre-hardened mold steel that is ideal for making injection molds that require high dimensional accuracy and surface finish. It is commonly used in the production of complex automotive parts where precision is critical. The steel’s uniform hardness and machinability make it a popular choice for mold makers.

S50C Steel: S50C is a carbon steel with a high carbon content, providing increased hardness and strength. It is particularly suited for molds that need to withstand high-pressure injection processes and high temperatures. S50C steel ensures nice durability and wear resistance, which is essential for molds subjected to repeated cycles and stress.

S45 Steel: This is another high-carbon steel with balanced properties of strength and hardness. S45 steel is often used in molds that require a combination of toughness and resistance to impact. Its ability to maintain dimensional stability under pressure makes it suitable for a wide range of automotive parts.

2. High Precision and Durability

Our injection molds are engineered to achieve high levels of precision and durability. The use of advanced machining techniques and high-quality mould steels ensures that every mold meets the exact specifications required for automotive parts.

The durability of our molds means they can withstand the rigors of high-volume production without compromising quality. This results in fewer mold changes and lower production costs over time, making our molds a cost-effective choice for manufacturers.

3. Enhanced Performance

The design of our automotive parts molds focuses on enhancing performance in various aspects:

Temperature Control: Effective temperature control is essential for consistent part quality and mold longevity. Our molds are designed with advanced cooling and heating systems to maintain optimal temperatures throughout the injection process, ensuring uniform cooling and reducing cycle times.

Wear Resistance: The selection of high-grade mould steels, such as P20, S50C, and S45, enhances wear resistance, reducing the need for frequent maintenance and extending the mold's service life. This is particularly important for high-volume production where consistent performance is required.

Surface Finish: Our molds are crafted to achieve surface finishes on the automotive parts. This not only enhances the aesthetic appeal of the parts but also improves their functionality and performance. The smooth surface finish also reduces the need for post-processing, saving time and cost.

4. Customization and Flexibility

We understand that different automotive parts have unique requirements. Our injection molds can be customized to meet specific design and functional needs. Whether it's for intricate components or large, robust parts, we offer flexibility in mold design and construction to accommodate a wide range of applications.

5. Efficient Production

The efficiency of our injection molds contributes to faster production cycles and higher output. With precise engineering and high-quality materials, our molds enable smooth and efficient production processes, reducing downtime and increasing overall productivity. This efficiency is crucial for meeting the high demands of the automotive industry.