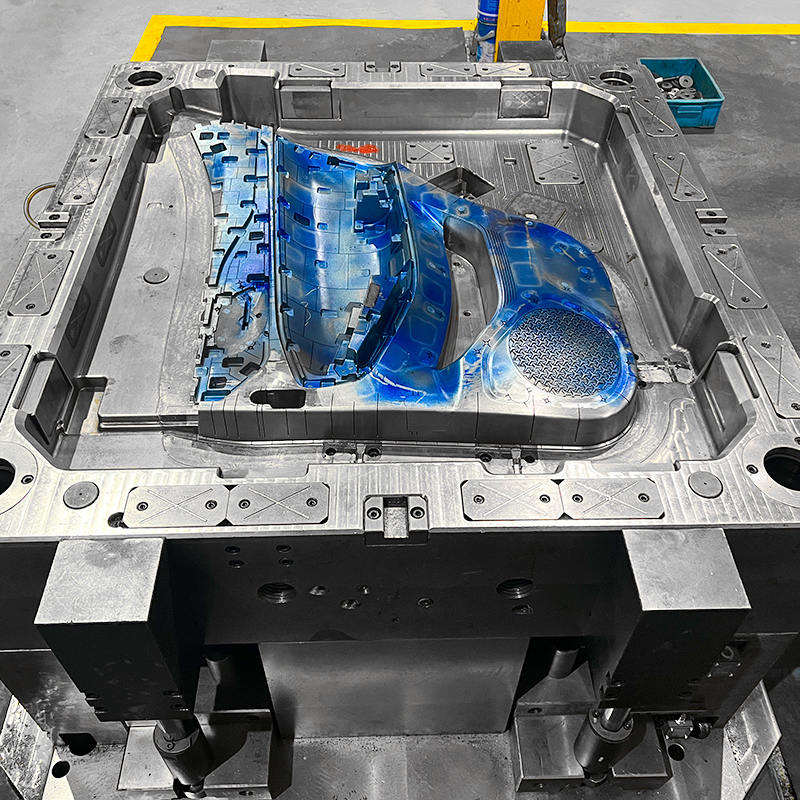

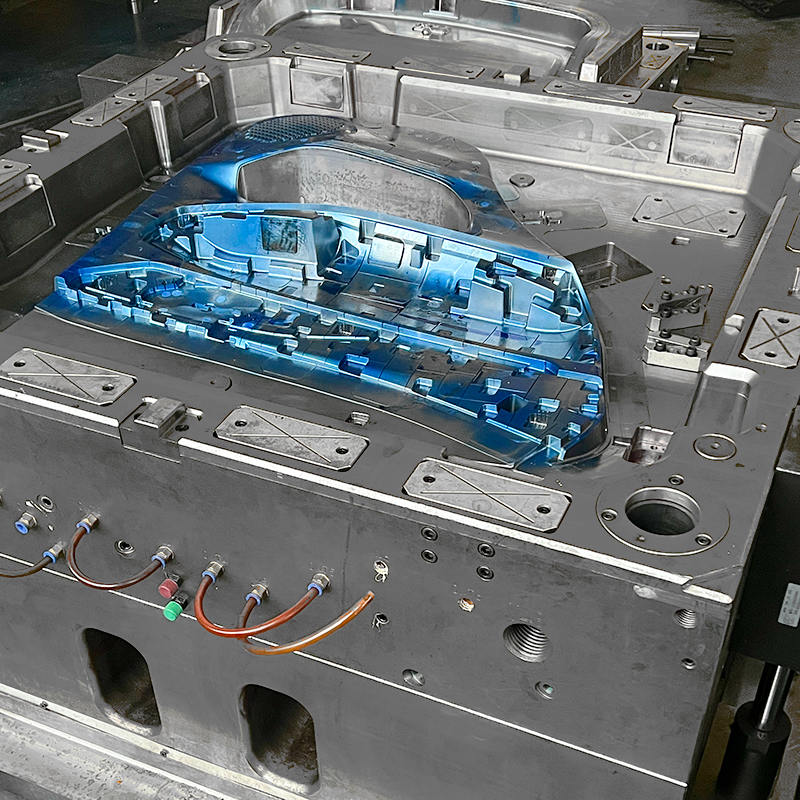

Automotive Light Mould

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

54 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

Automotive light molds are specialized tools used in the injection molding process to produce various components of automotive lighting systems. These molds are crafted to create parts such as headlamp lenses, tail light housings, turn signal covers, and fog light assemblies. They are engineered to handle high temperatures and pressures typical in the molding process, ensuring durability and high-quality output.

The primary function of automotive light molds is to achieve exact replication of the intricate designs and specifications required for automotive lighting components. This includes complex geometries, precise dimensions, and surface finishes that meet stringent industry standards. Automotive light molds are made from high-quality steel or aluminum alloys, which provide the necessary strength and thermal conductivity for efficient molding.

Advantages

High Precision and Consistency

Accuracy: Automotive light molds are engineered with precise tolerances to ensure that each part produced meets exact specifications. This precision is crucial for fitting components correctly and ensuring uniform light distribution.

Consistency: The molds are designed to produce consistent results across multiple cycles, which is essential for maintaining high standards in automotive lighting components.

Durability and Longevity

Material Quality: Made from high-strength materials, automotive light molds can withstand the wear and tear of continuous use. This durability reduces the need for frequent replacements and maintenance.

Temperature Resistance: The molds are built to endure the high temperatures involved in the injection molding process, ensuring that they perform reliably over extended periods.

Cost-Efficiency

Reduced Production Costs: The high efficiency and precision of automotive light molds lead to lower production costs. Accurate molds reduce material waste and minimize the need for post-production adjustments.

Improved Cycle Times: High-quality molds enable faster production cycles, which contributes to increased output and reduced manufacturing costs.

Key Features

Advanced Design and Engineering

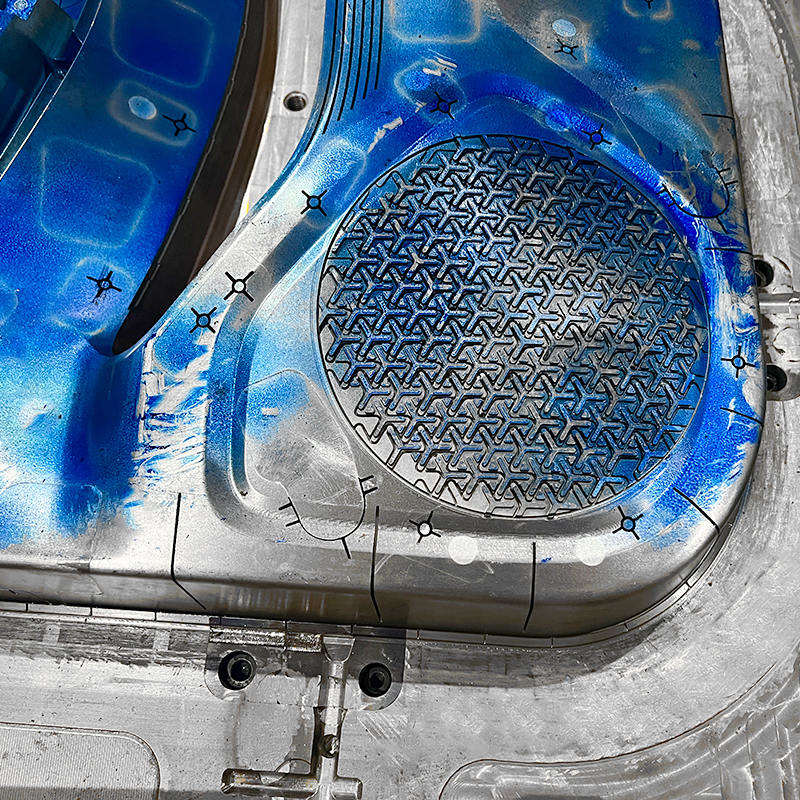

Complex Geometries: Automotive light molds are designed to handle complex shapes and detailed features required for modern automotive lighting systems. This includes intricate lens designs and multi-part assemblies.

Customization: Molds can be customized to meet specific design requirements, allowing for the production of a wide range of light components tailored to different vehicle models and lighting technologies.

High-Quality Material Construction

Steel and Aluminum Alloys: The use of high-quality steel and aluminum alloys ensures that the molds are robust and capable of withstanding the pressures and temperatures of the molding process.

Surface Finishes: Molds are treated to provide smooth surface finishes that reduce the risk of defects in the final products, such as scratches or blemishes on light lenses.

Precision Injection Molding

Injection Mechanism: Automotive light molds feature advanced injection mechanisms that ensure precise filling of the mold cavities. This precision is critical for producing components with accurate dimensions and consistent quality.

Cooling Systems: Efficient cooling systems integrated into the molds help control the temperature during the molding process, reducing cycle times and improving the quality of the molded parts.

Why Automotive Light Molds Are Essential

Automotive light molds play a crucial role in the production of high-quality automotive lighting components. They are essential for ensuring that vehicle lights meet regulatory standards for safety and performance. The precision and consistency provided by these molds contribute to the overall quality and reliability of automotive lighting systems.

In addition to meeting technical specifications, automotive light molds also enable manufacturers to innovate and develop new lighting designs. As automotive lighting technology evolves, molds must adapt to accommodate new shapes, materials, and functionalities. This adaptability is vital for staying competitive in the rapidly changing automotive industry.