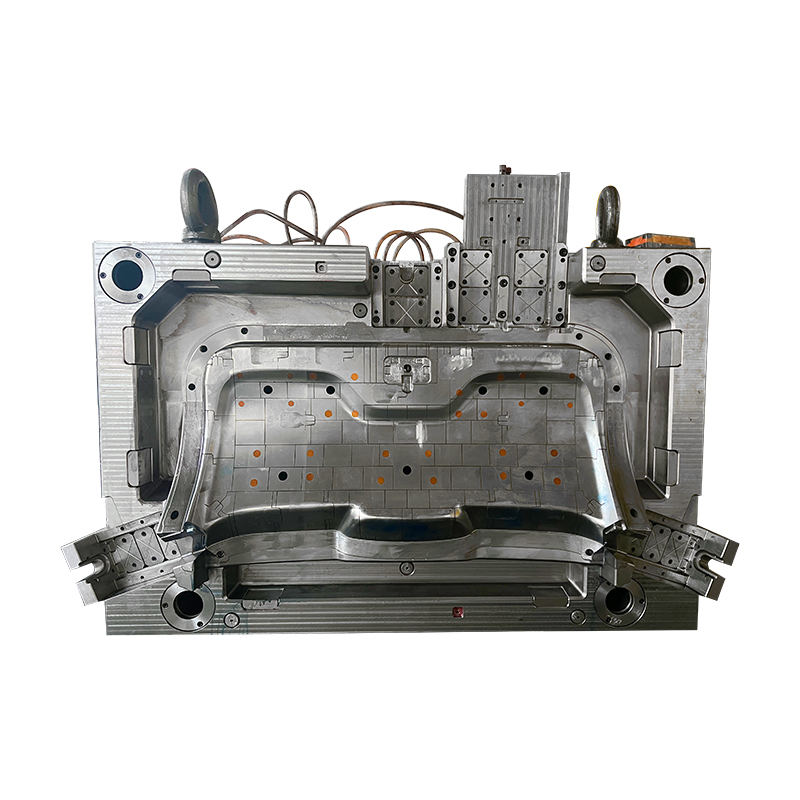

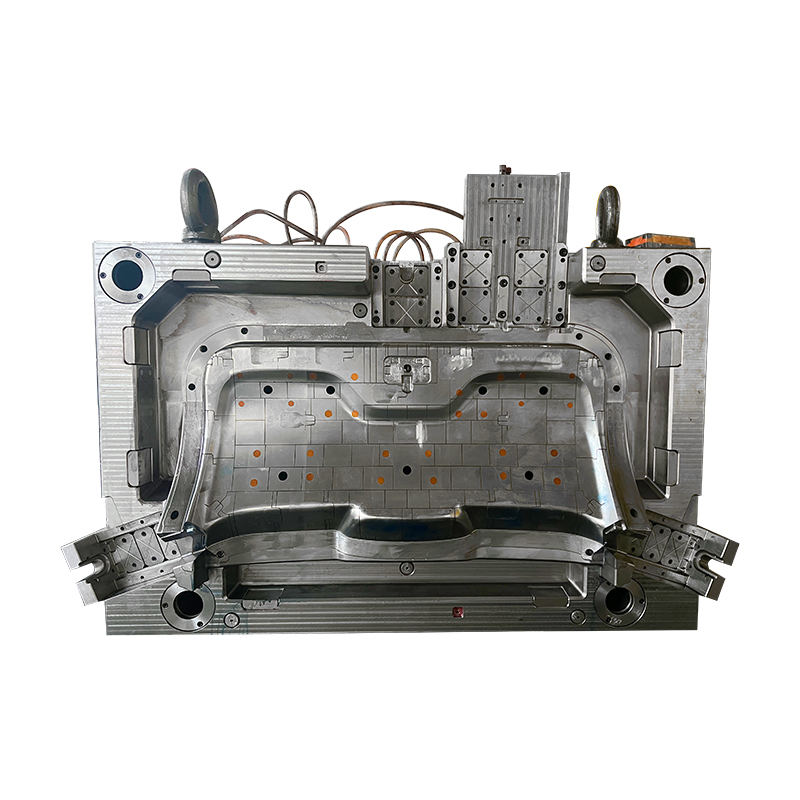

Automotive Rear Bumper Mold

|

Product Application |

automotive |

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

50 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The Automotive Rear Bumper Mold employs a compression moulding process. Compression moulding is a technique where the mold is heated and then compressed with a specific amount of material to shape it. This method is particularly suitable for producing large, complex parts like rear bumpers due to its ability to create parts with high structural integrity and dimensional accuracy. Compression moulding ensures that the material is evenly distributed throughout the mold, reducing defects and ensuring uniform quality.

Key Features and Advantages

1. Versatile Mould Configurations

Single Cavity Mould: The single cavity configuration is ideal for production runs where only one rear bumper design is required. It allows for high precision and is particularly useful for prototyping or low-volume production. The single cavity mold ensures that each bumper produced has consistent quality and dimensional accuracy.

Multiple Cavities Mould: The multiple cavities configuration allows for the production of several bumpers simultaneously. This setup is designed for medium to high-volume production, optimizing efficiency and reducing cycle times. By using multiple cavities, manufacturers can increase output without compromising on quality, making it a cost-effective choice for larger production runs.

Multiple Cavities with Interchangeable Inserts: This configuration offers the flexibility by allowing different designs to be produced with the same mold. The interchangeable inserts enable manufacturers to switch between different bumper designs quickly, which is particularly useful for automotive companies that need to adapt to changing market demands or produce a range of bumper styles. This setup maximizes the mold’s versatility and efficiency, providing a high return on investment.

2. High-Quality Material Processing

Durability and Strength: The mold is designed to handle high-pressure compression, making it suitable for materials that require significant force to shape. This ensures that the final bumper product is robust and durable, capable of withstanding the stresses and impacts experienced in real-world automotive applications.

Precision Engineering: The Automotive Rear Bumper Mold is engineered with meticulous attention to detail, ensuring that each part produced meets strict quality standards. The precision of the mold reduces the likelihood of defects and variations, resulting in a consistent product that fits goodly in the vehicle’s rear assembly.

Efficient Heat Distribution: The mold's design includes features that promote even heat distribution during the compression process. This ensures that the material cures uniformly, to better surface finishes and reducing the likelihood of defects such as warping or incomplete filling.

3. Cost-Effectiveness and Efficiency

Reduced Cycle Times: The mold's design and the compression moulding process contribute to shorter cycle times compared to other molding techniques. This increased efficiency translates into higher production rates and lower per-unit costs, making it a cost-effective solution for manufacturers.

Lower Maintenance Costs: The robust construction and high-quality materials used in the mold’s manufacturing reduce the need for frequent maintenance and repairs. This reduces downtime and ensures a longer service life for the mold, further enhancing its cost-effectiveness.

Applications

The Automotive Rear Bumper Mold is used extensively in the automotive industry for producing rear bumpers that meet safety, aesthetic, and functional requirements. It is suitable for:

Mass Production: Ideal for large-scale manufacturing of rear bumpers for various vehicle models, ensuring consistency and high output.

Prototype Development: Useful for developing and testing new bumper designs before moving into full-scale production.

Customization: Allows for the production of customized bumpers with different designs and features, catering to specific market needs or customer preferences.