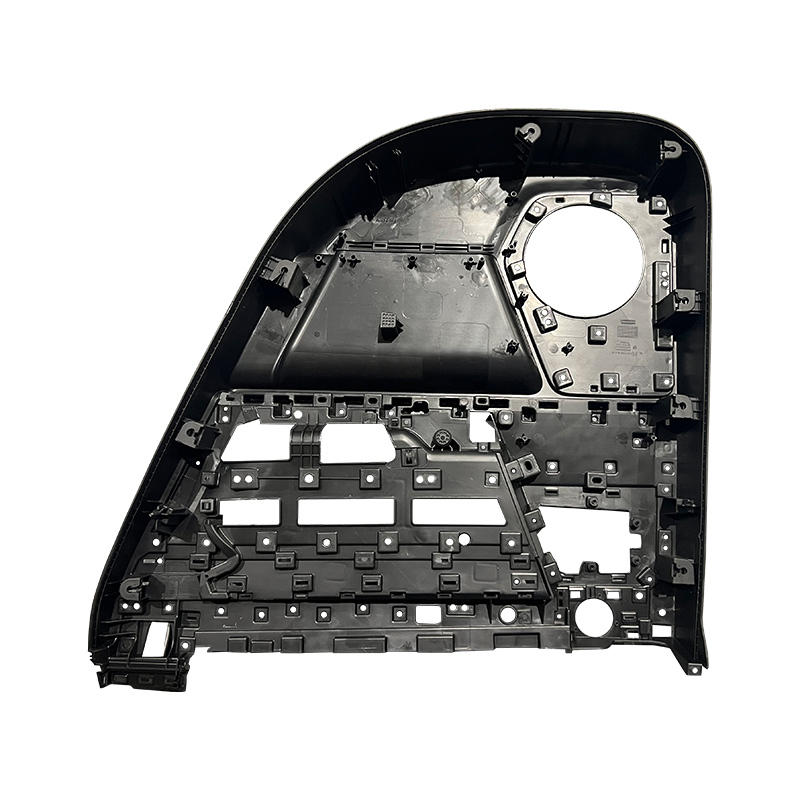

Automotive Left Rear Door Trim Panel Mold

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

58 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The Automotive Left Rear Door Trim Panel Mold is engineered for precision and durability, utilizing advanced compression molding technology. This type of mold is specifically designed to produce the left rear door trim panels that enhance both the interior design and functionality of vehicles. The mold is constructed with high-grade materials to withstand the rigors of repeated use while delivering consistent, high-quality results.

Key Features

Precision Engineering:

High Accuracy:The mold is crafted with meticulous attention to detail, ensuring that each trim panel produced fits goodly in the vehicle's left rear door.

Customizable Design:It can be tailored to accommodate various design specifications and vehicle models, providing flexibility for manufacturers.

Durable Construction:

Robust Materials:Made from high-strength steel and other durable materials, the mold is built to endure the pressures of the compression molding process.

Long Lifespan:The use of high-quality materials and advanced manufacturing techniques ensures a long operational life with fewer maintenance requirements.

Efficient Production:

Fast Cycle Times:The mold is designed to optimize the compression molding process, resulting in quick production cycles and increased throughput.

High Yield:It ensures fewer material wastage and high production efficiency, which helps in reducing overall manufacturing costs.

Advantages

Enhanced Aesthetic Appeal:

Smooth Finish:The mold produces trim panels with a smooth, high-quality finish, enhancing the overall look and feel of the vehicle interior.

Customization Options:Allows for various surface textures and finishes to meet the specific design requirements of different vehicle models.

Improved Durability and Functionality:

Strength and Longevity:The trim panels produced are durable and resistant to wear and tear, ensuring they perform well over the lifespan of the vehicle.

Functional Design:Designed to include features such as mounting points and cutouts that align with vehicle assembly requirements.

Cost-Effectiveness:

Reduced Production Costs:The efficiency of the compression molding process helps in reducing material costs and manufacturing expenses.

Low Maintenance:The durable construction of the mold translates into lower maintenance costs and fewer downtime incidents.

User-Friendly Design:

Ease of Operation:The mold is designed for ease of use in production environments, with straightforward setup and operation processes that minimize training time and operational errors.

Compatibility:It integrates seamlessly with existing molding machinery, ensuring smooth adaptation to different manufacturing setups.

Applications

Automotive Manufacturing:

Mass Production:Ideal for high-volume production runs, making it suitable for automotive manufacturers needing to produce trim panels for various vehicle models.

Aftermarket Parts:Also used in the production of aftermarket trim panels, catering to the needs of vehicle repair and customization.

Custom Vehicle Design:

Specialty Vehicles:Can be adapted for use in producing trim panels for specialty or custom vehicles, offering design flexibility and customization options.

Interior Enhancements:Supports the creation of trim panels with unique features and finishes to meet specific customer preferences and design standards.

The Automotive Left Rear Door Trim Panel Mold represents a critical component in the automotive manufacturing process. With its advanced compression molding technology, durable construction, and precise engineering, it ensures the production of high-quality, functional, and aesthetically pleasing trim panels. Whether for standard automotive manufacturing or specialty applications, this mold delivers good performance and reliability.