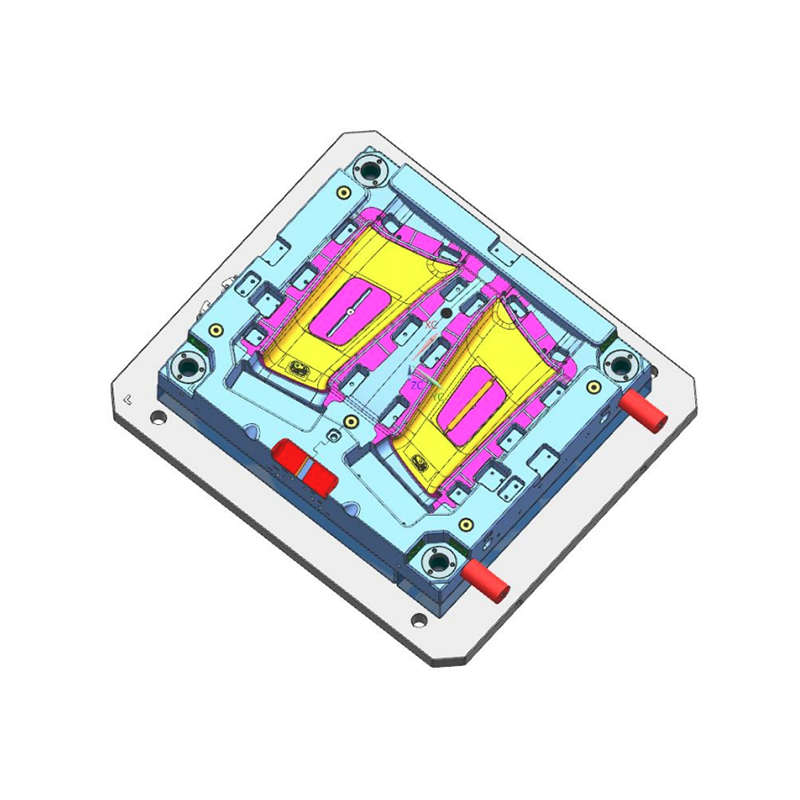

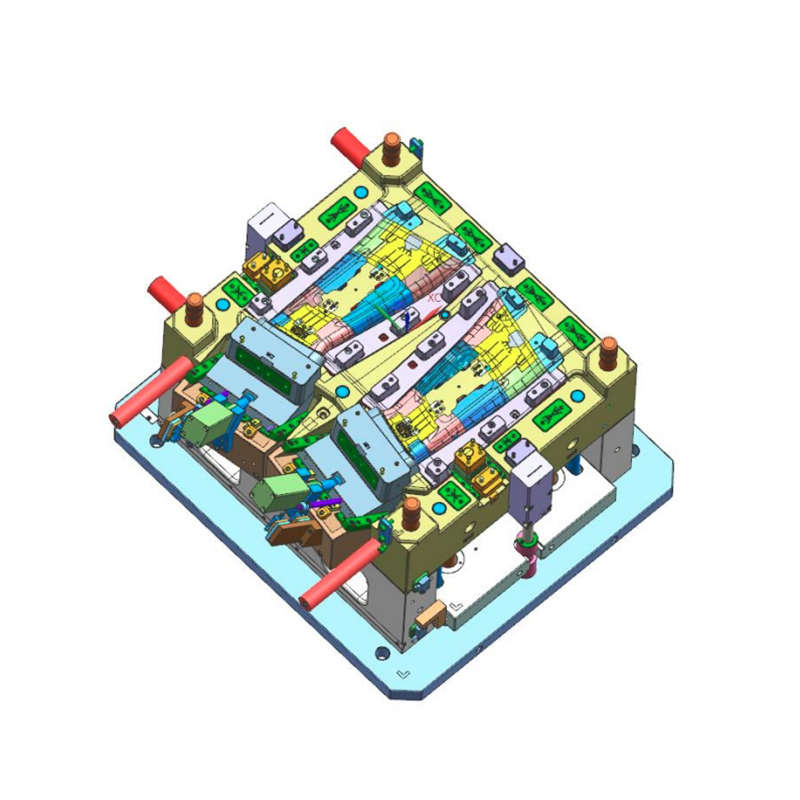

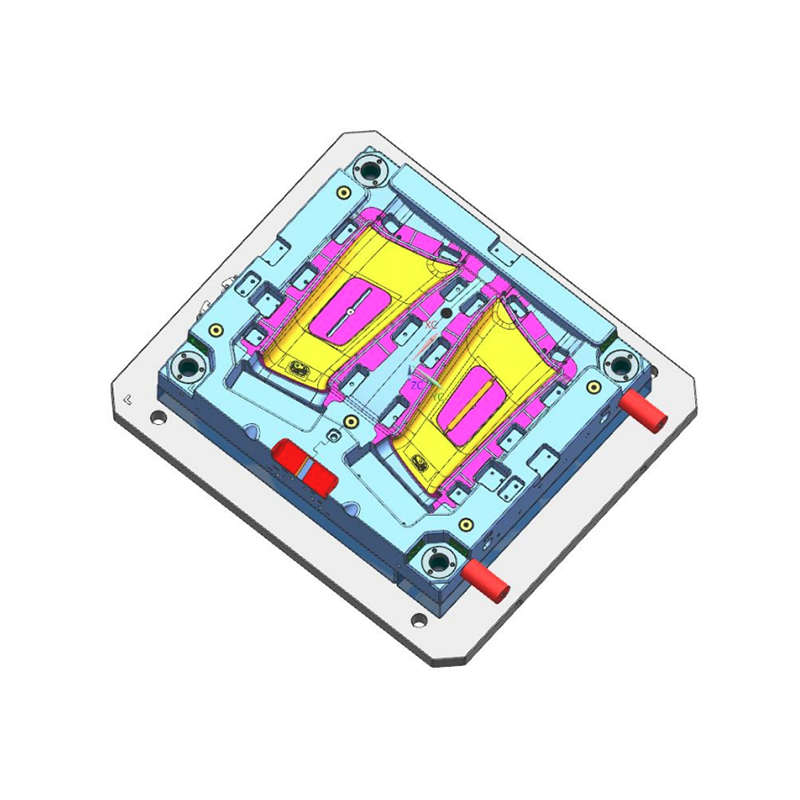

EP40 Left and Right Upper B-Pillars of Hezhong Automobile

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

75 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The EP40 Left and Right Upper B-Pillars are integral components of the vehicle’s body structure, positioned between the front and rear doors. These pillars play a vital role in maintaining the vehicle’s structural rigidity and passenger safety, particularly during side-impact collisions. Made from advanced composite materials, the EP40 B-Pillars are designed to withstand significant forces, contributing to the overall safety and stability of the vehicle.

1. Design and Engineering

Precision Engineering: The EP40 B-Pillars are engineered with a focus on precision, ensuring a good fit and alignment within the vehicle’s structure. Our design process incorporates the late technological advancements and stringent quality controls.

Composite Materials: Utilizing high-performance composite materials, the B-Pillars offer strength-to-weight ratio, enhancing both safety and fuel efficiency. These materials are also resistant to corrosion and wear, extending the lifespan of the components.

Customization: We provide tailored solutions to meet specific customer requirements, including modifications to accommodate different vehicle models and design specifications.

2. Manufacturing Process

Advanced Moulding Techniques: At Liberal Mould, we employ advanced composite moulding and injection moulding techniques to produce the EP40 B-Pillars. This ensures consistent quality and high production efficiency.

Quality Assurance: Each component undergoes rigorous testing and quality assurance processes to meet automotive industry standards. Our comprehensive testing protocols include impact resistance tests and dimensional accuracy checks.

Integration and Assembly: Designed for ease of integration into the vehicle’s body, the EP40 B-Pillars facilitate smooth assembly and contribute to the overall structural integrity of the automobile.

Advantages of EP40 B-Pillars

1. Enhanced Safety

Structural Integrity: The EP40 B-Pillars are designed to absorb and dissipate impact forces, reducing the risk of injury during collisions. This enhances the safety of passengers and drivers.

Durability: The use of high-strength composite materials ensures that the B-Pillars maintain their structural integrity over time, even under harsh conditions.

2. Improved Performance

Weight Efficiency: The composite materials used in the EP40 B-Pillars are lightweight, contributing to overall vehicle weight reduction and improved fuel efficiency without compromising safety.

Corrosion Resistance: The B-Pillars are resistant to corrosion and environmental damage, ensuring long-term performance and reduced maintenance needs.

3. Customizable Solutions

Tailored Design: Liberal Mould offers customized design solutions to meet specific requirements of different vehicle models, ensuring that the B-Pillars fit goodly and function optimally.

Flexible Production: Our manufacturing capabilities allow for flexible production runs, accommodating both small and large quantities as per customer needs.

Why Choose Liberal Mould?

1. Expertise and Innovation

Liberal Mould specializes in composite and injection moulding, with extensive experience in developing high-quality automotive parts. Our innovative approach and commitment to fineness ensure that each product meets high standards of performance and reliability.

2. Comprehensive Services

From initial design and mould development to final production, we provide a comprehensive range of services tailored to our customers’ needs. Our one-off solution approach guarantees a seamless process and good results.

3. Customer-Centric Approach

We prioritize customer satisfaction and work closely with clients to understand their requirements and deliver tailored solutions. Our dedicated team of experts is committed to providing support and ensuring that our products meet or exceed expectations.

In conclusion, the EP40 Left and Right Upper B-Pillars for Hezhong Automobile represent a blend of advanced engineering, high-quality materials, and meticulous craftsmanship. By choosing Liberal Mould, you benefit from our expertise in composite and injection moulding, along with our commitment to delivering automotive components that enhance safety, performance, and durability.