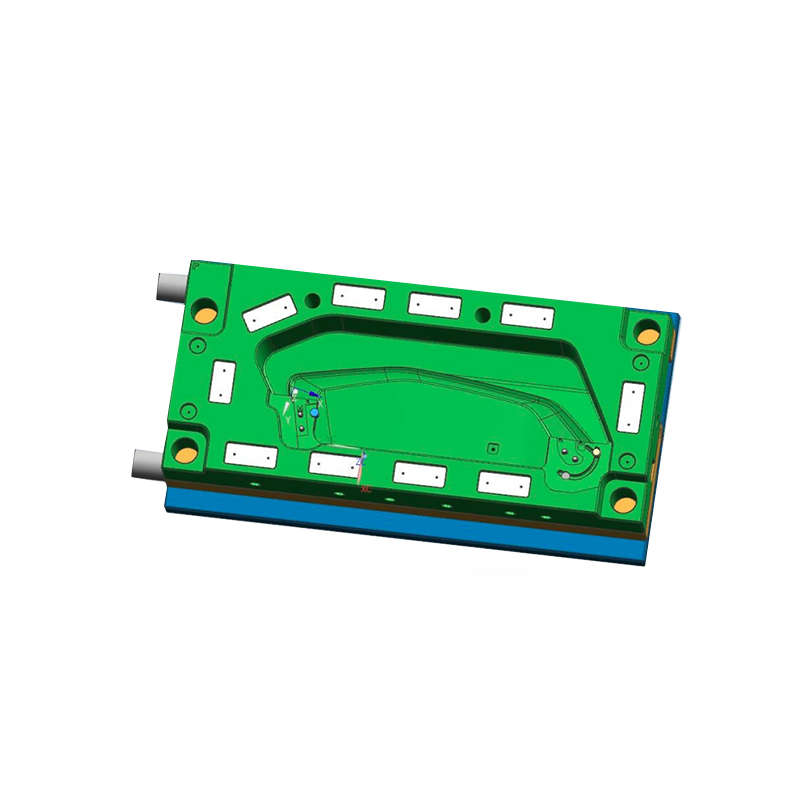

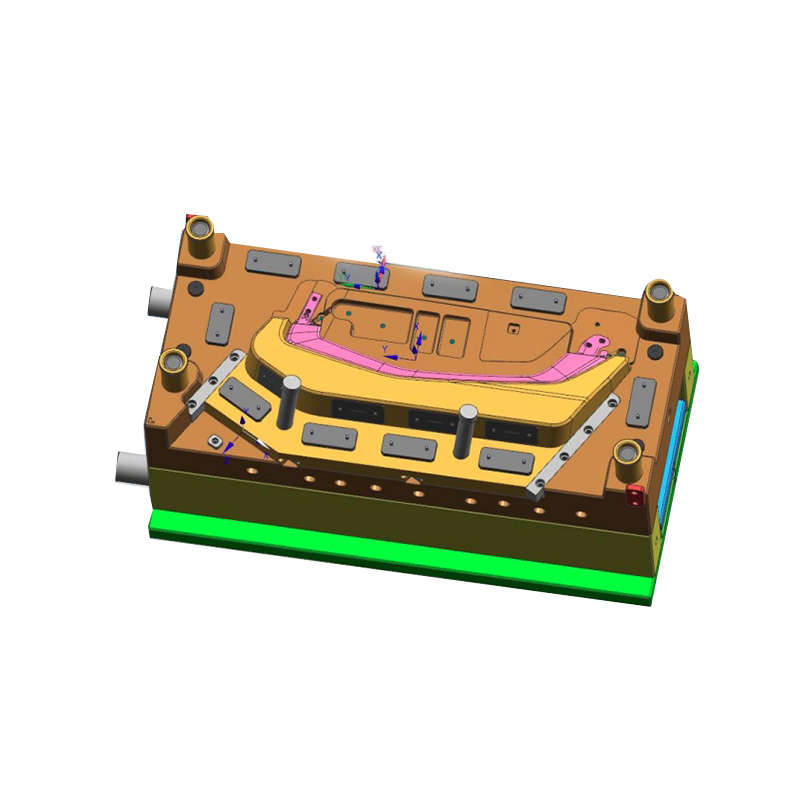

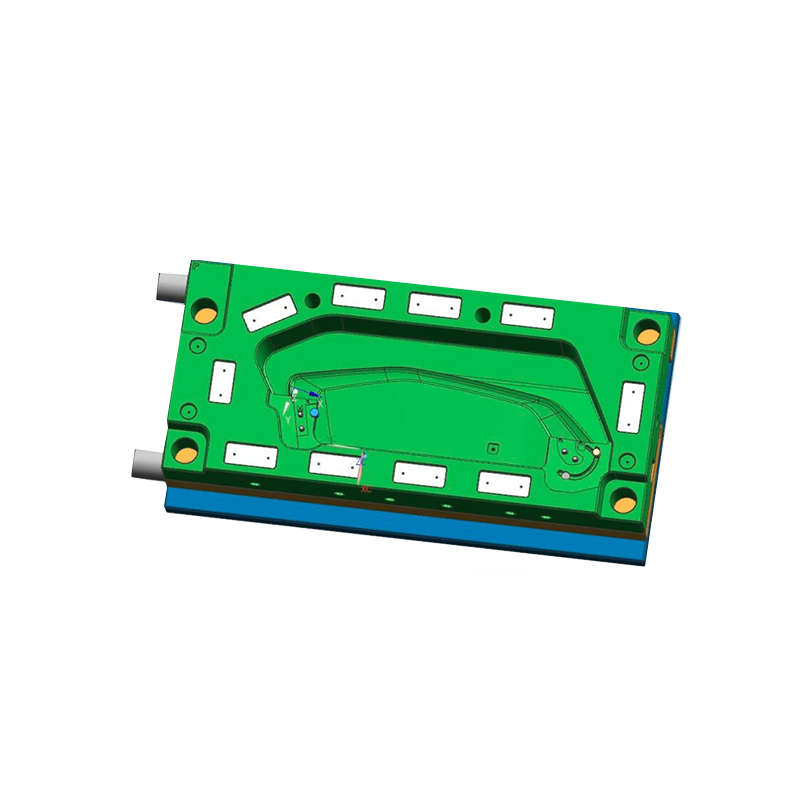

Jiangling N806 Handle (Injection Molding+gas Assisted)

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

79 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The Jiangling N806 Handle is a high-quality automotive component designed with advanced manufacturing techniques, specifically injection molding combined with gas-assisted technology. This handle is engineered to meet the rigorous demands of the automotive industry, ensuring durability, strength, and aesthetic appeal. It represents a good blend of functionality and design, tailored to fit the specifications of Jiangling vehicles.

Key Features

1. Advanced Injection Molding Technique

The Jiangling N806 Handle is produced using sophisticated injection molding processes, which ensure precision and consistency in the final product. Injection molding is a method that allows for the mass production of complex parts with high dimensional accuracy, making it ideal for automotive components that require exact specifications. The technique ensures that each handle produced meets the stringent quality standards expected in the automotive industry.

2. Gas-Assisted Injection Molding

To enhance the product's structural integrity and reduce weight, gas-assisted injection molding is employed. This process involves injecting a gas (usually nitrogen) into the mold cavity after the molten plastic has been introduced. The gas pushes the plastic into the desired shape while also creating a hollow section within the part. This technique not only reduces the material usage but also reduces internal stress and warping, resulting in a stronger and lighter handle. The gas-assisted process is particularly beneficial for parts like the Jiangling N806 Handle, where strength and weight are critical factors.

3. Material Quality

The material used in the production of the Jiangling N806 Handle is carefully selected to meet the demanding conditions of automotive use. The handle is made from high-grade composite materials, which offer nice resistance to wear and tear, UV radiation, and environmental factors. The combination of durable materials and advanced manufacturing processes ensures that the handle maintains its integrity and appearance over time, even under harsh conditions.

4. Customization and Precision

Liberal Mould, the manufacturer behind the Jiangling N806 Handle, specializes in composite and injection molds. The company’s expertise allows for high levels of customization according to customer requirements. Whether it’s the design, dimensions, or specific functional features, the handle can be tailored to meet the exact needs of the client. The precision engineering involved ensures that the handle fits goodly within the Jiangling vehicle’s overall design, providing a seamless integration.

Advantages of Jiangling N806 Handle

1. Enhanced Durability and Strength

The use of gas-assisted injection molding significantly enhances the durability and strength of the Jiangling N806 Handle. The hollow structure created during the gas-assisted process reduces the risk of stress-related fractures and improves the handle’s overall robustness. This makes the handle more resistant to mechanical impacts and environmental wear, ensuring a longer lifespan.

2. Lightweight Design

One of the key benefits of gas-assisted injection molding is the ability to produce lightweight components without compromising strength. The Jiangling N806 Handle is designed to be lighter than traditional solid handles, contributing to the overall efficiency of the vehicle by reducing its weight. This is particularly important in the automotive industry, where every gram counts towards improving fuel efficiency and vehicle performance.

3. Aesthetic and Functional Integration

The Jiangling N806 Handle is not only functional but also aesthetically pleasing. The precision of the injection molding process ensures that the handle has a smooth finish with no visible defects, enhancing the overall appearance of the vehicle’s interior or exterior. The ability to customize the design also means that the handle can be made to match the vehicle’s aesthetic, providing a cohesive look.