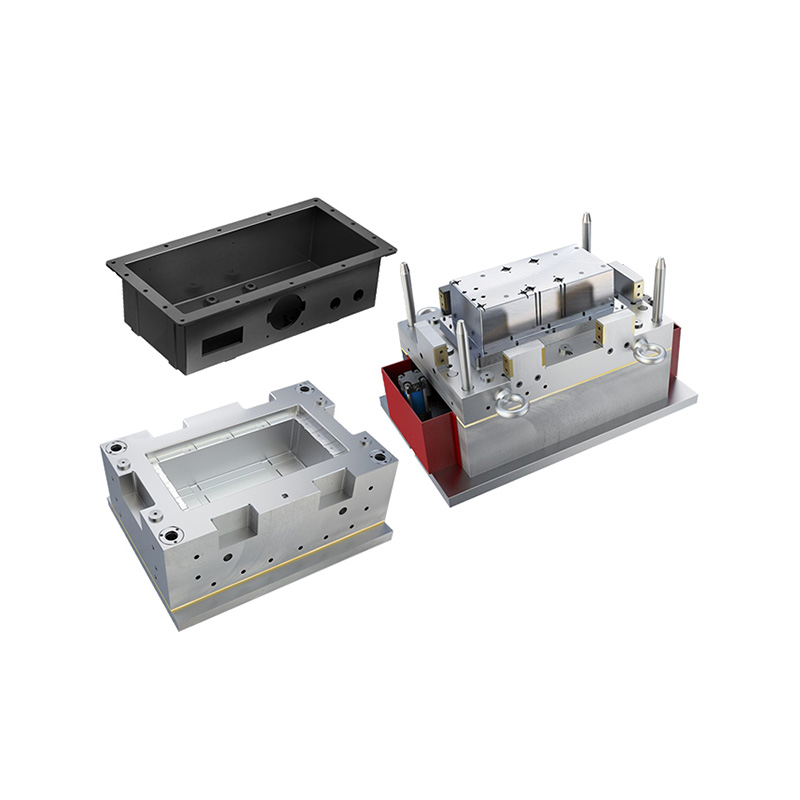

SMC Circuit Breaker Box Mould

|

Product Application |

fire-fighting equipment, construction sites, infrastructure, sites |

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

50 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The SMC Circuit Breaker Box Mould is a advanced product designed for the manufacture of circuit breaker boxes using Sheet Molding Compound (SMC) material. This mould is meticulously crafted to leverage the unique properties of SMC, making it an ideal choice for industries that require both strength and weight reduction.

Advantages of SMC Material

1. Strength and Weight Reduction:

High Strength-to-Weight Ratio: SMC material offers an impressive strength-to-weight ratio, making it good for applications where both durability and lightweight characteristics are crucial. The circuit breaker boxes produced using this mould are strong enough to withstand harsh environments while remaining easy to handle and install.

Structural Integrity: The composite nature of SMC ensures that the final product maintains its structural integrity even under stress, reducing the risk of damage or failure in critical applications.

2. Versatility in Application:

Moldability: SMC is a highly moldable material that can be formed into various shapes and sizes. This flexibility allows the SMC Circuit Breaker Box Mould to produce enclosures that are tailored to specific needs across different industries.

Wide Range of Applications: The versatility of SMC makes it suitable for a wide range of applications, including water treatment, electrical installations, construction projects, infrastructure development, and the manufacturing industry. The mould can be customized to meet the unique requirements of each sector, ensuring optimal performance.

3. Special Properties:

Electrical Insulation: SMC is an nice electrical insulator, which is essential for circuit breaker boxes. This property ensures that the enclosures provide a safe and reliable environment for electrical components, reducing the risk of electrical failures or hazards.

Corrosion Resistance: The SMC material is inherently resistant to corrosion, making it ideal for use in environments where exposure to moisture, chemicals, or other corrosive elements is common.

Flame Retardancy: SMC is also known for its flame-retardant properties, providing an additional layer of safety in electrical installations.

Key Features of SMC Circuit Breaker Box Mould

1. High-Quality Mould Steel:

P20 / S50C / S45 Steel: The SMC Circuit Breaker Box Mould is made from high-quality steel, including P20, S50C, and S45 grades. These materials are chosen for their nice machinability, durability, and resistance to wear, ensuring that the mould delivers consistent performance over time.

Longevity: The use of premium mould steel not only enhances the durability of the mould itself but also contributes to the longevity of the final product. This means fewer replacements and lower costs for manufacturers in the long run.

2. Precision Engineering:

Accurate Moulding: The SMC Circuit Breaker Box Mould is designed with precision engineering to ensure that each product meets exact specifications. This accuracy is crucial in producing enclosures that fit goodly and function reliably in their intended applications.

Customizability: The mould can be customized to produce circuit breaker boxes of various sizes and shapes, allowing manufacturers to cater to different market demands. This flexibility is a significant advantage in a competitive industry where product differentiation is key.

3. Efficiency and Cost-Effectiveness:

Fast Production Cycles: The SMC Circuit Breaker Box Mould is optimized for efficiency, enabling faster production cycles without compromising on quality. This efficiency translates into cost savings for manufacturers, as it allows for higher output in less time.

Reduced Waste: The mould's design reduces material waste during the production process, further enhancing its cost-effectiveness.