Custom China inside of car mould manufacturers

In the automobile manufacturing industry, molds are an indispensable tool in the production process. They not only determine the shape and size of car parts, but also directly affect the quality of the final product. Today, I will delve into the importance of the inside of car mould and its role in the automobile manufacturing process from the perspective of the manufacturer.

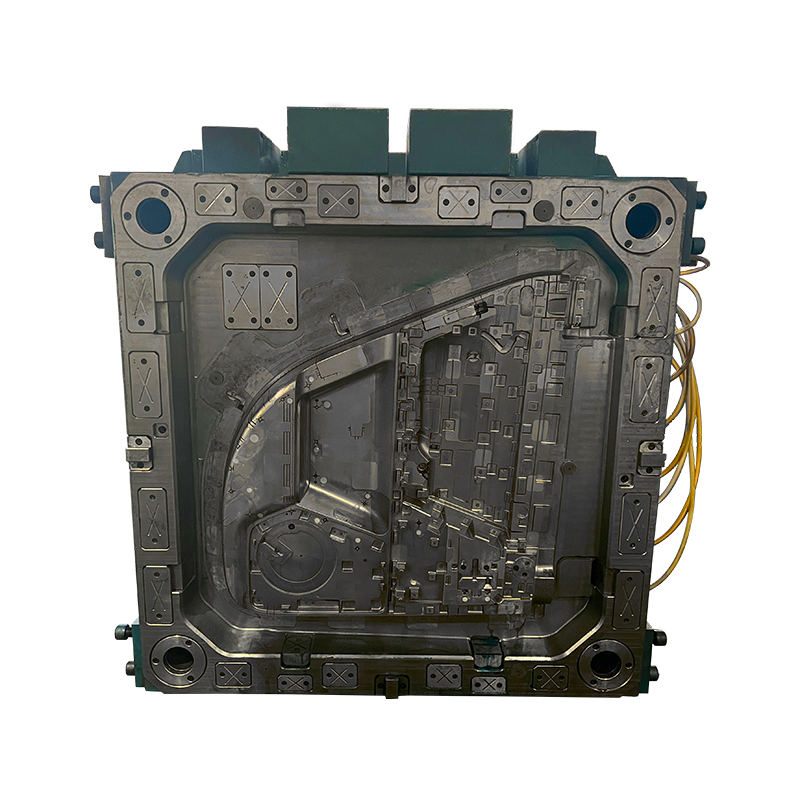

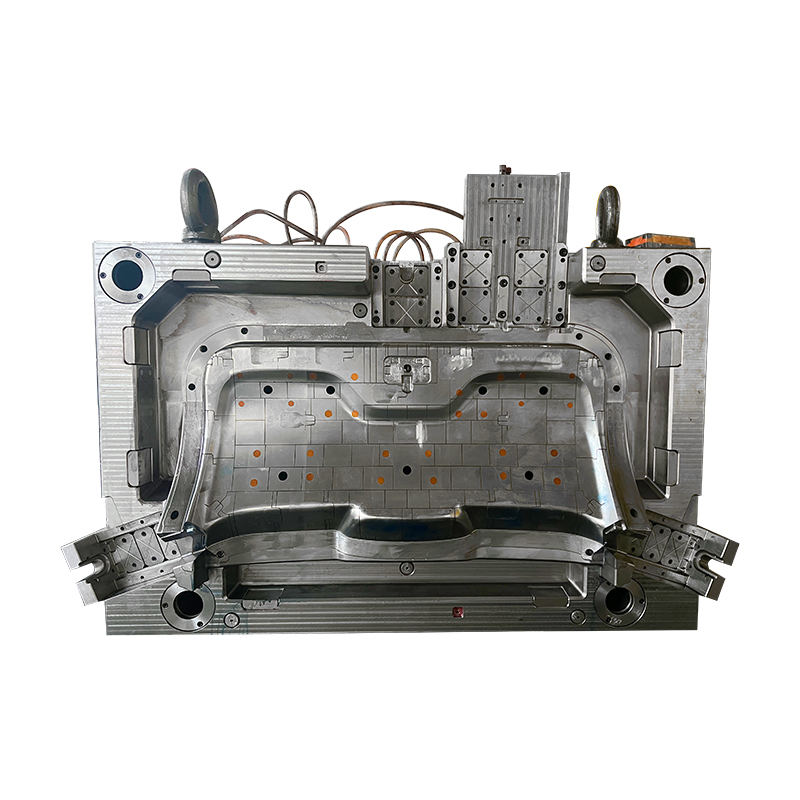

inside of car moulds, as the name suggests, are molds used to manufacture automotive interior parts. These molds are usually used to produce automobile dashboards, seats, door panels, center consoles and other components. Each in-house mold is carefully designed to ensure it accurately replicates the desired shape and size. During the design process, we will take into account various factors such as material fluidity, cooling speed, shrinkage rate, etc. to ensure the durability of the mold and the efficiency of production.

The design of inside of car moulds is a complex process. Designers need to design molds that are both beautiful and practical based on the interior space and functional requirements of the car. This requires not only an in-depth understanding of the internal structure of the car, but also a full mastery of materials, mechanics and other subjects.

Next, is the mold manufacturing process. inside of car moulds are usually made of high-strength steel or aluminum alloys. These materials not only have good mechanical properties, but can also withstand high-temperature and high-pressure working environments. During the manufacturing process, we use precision CNC machining technology to ensure the dimensional accuracy and surface finish of the mold. In addition, we also perform heat treatment and surface treatment on the mold to improve its wear resistance and corrosion resistance.

Mold debugging and trial production are also important links in the automotive internal mold manufacturing process. At this stage, we will carefully inspect and adjust the mold to ensure that it can stably produce parts that meet the design requirements. At the same time, we will also conduct trial production to test the performance and production efficiency of the mold. Only when the mold passes rigorous testing and evaluation will we put it into formal production.

In the production process of inside of car moulds, quality control is crucial. We will conduct strict inspections on every produced part to ensure that its size, shape and surface quality meet standards. In addition, we perform regular maintenance and upkeep on the molds to extend their service life and ensure production efficiency.

Innovation in inside of car moulds is also a goal we are constantly pursuing. With the rapid development of the automobile industry, consumers have higher and higher demands for comfort and personalization in automobile interiors. In order to meet these needs, we will continue to develop new mold technologies, such as 3D printing molds, smart molds, etc., to improve production efficiency and product quality.

The sustainability of inside of car moulds is also a focus for us. During the design and manufacturing process, we will try our best to choose environmentally friendly materials and processes to reduce the impact on the environment. At the same time, we will also reduce energy consumption and waste generation by optimizing mold design and production processes.

In short, inside of car moulds play a vital role in the automotive manufacturing process. From design to manufacturing, to quality control and innovation, every aspect requires us to strive for excellence and continue to pursue excellence. As a manufacturer, we are well aware of our responsibilities and are committed to providing consumers with high-quality, high-performance automotive interior parts and making our contribution to the development of the automotive industry.