The emergence of SMC (Sheet Molding Compound) sewage treatment injection molds marks a significant advancement in environmental engineering and infrastructure development. These specialized molds play a crucial role in manufacturing durable and efficient components for sewage treatment systems, ensuring effective wastewater management and environmental sustainability.

Evolution of SMC Sewage Treatment Injection Mould Company

SMC sewage treatment injection molds have evolved in response to growing global concerns over water pollution and the need for sustainable wastewater treatment solutions. As urbanization accelerates and populations increase effective sewage treatment becomes imperative to protect public health and the environment. The development of SMC molds has enabled manufacturers to produce robust and corrosion-resistant components essential for sewage treatment plants and systems.

Characteristics of SMC Sewage Treatment Injection Mould

Material Composition: SMC molds are fabricated using a composite material consisting of thermosetting resins, glass fibers, and fillers. This composition offers mechanical strength, chemical resistance, and dimensional stability, making SMC an ideal choice for sewage treatment applications.

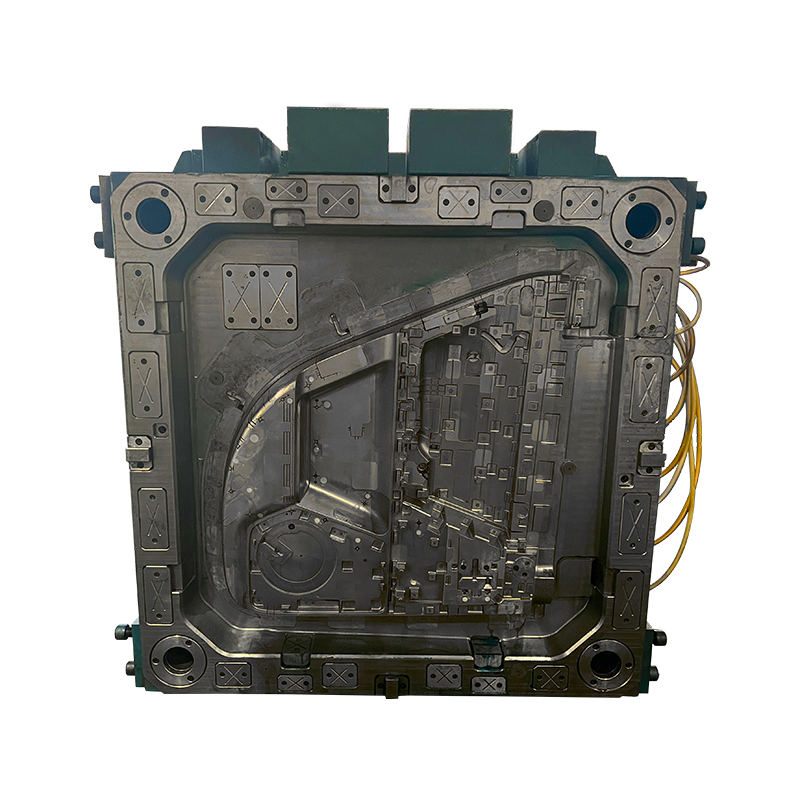

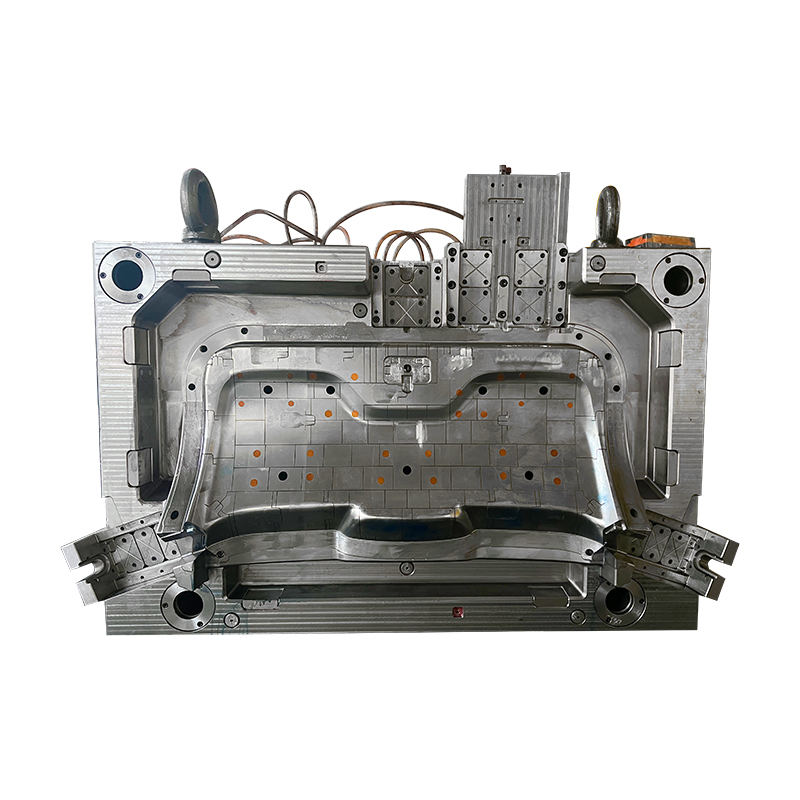

Design Precision: SMC sewage treatment molds company are engineered with precise cavity dimensions and complex geometries to mold components such as tanks, covers, and filtration systems. CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technologies ensure accurate mold design and optimization of material distribution.

Durability and Longevity: The inherent properties of SMC, including resistance to corrosion, UV degradation, and microbial attack, contribute to the long-term durability of sewage treatment components. SMC molds withstand harsh environmental conditions and operational stresses typical in sewage treatment facilities.

Applications of SMC Sewage Treatment Injection Mould Company

SMC sewage treatment injection molds find extensive applications across various sectors involved in wastewater management:

Municipal Sewage Treatment Plants: Components molded by SMC molds, such as tanks, channels, and covers, are integral to the efficient operation and treatment processes of municipal sewage treatment plants.

Industrial Wastewater Treatment: SMC molds cater to industrial applications requiring durable and chemical-resistant components for treating complex wastewater streams generated by manufacturing processes.

Septic Systems: SMC sewage treatment molds are used in the production of septic tanks and drainage systems, providing reliable solutions for residential and commercial properties without access to centralized sewage networks.

Environmental Impact and Sustainability

The adoption of SMC sewage treatment injection molds company aligns with global initiatives to improve water quality and environmental sustainability. By manufacturing components that resist degradation and require minimal maintenance, SMC molds contribute to reducing lifecycle costs and conserving natural resources. Furthermore, the longevity and reliability of SMC sewage treatment components support efficient wastewater management practices, and environmental impact and promote sustainable development.

Technological Advancements and Innovations

Advancements in SMC technology continue to enhance the capabilities and applications of sewage treatment injection molds. Innovations in resin formulations, reinforcement fibers, and molding techniques enable manufacturers to produce lighter, stronger, and more cost-effective sewage treatment components. Additionally, digital simulation tools and predictive modeling optimize mold design and manufacturing processes, improving efficiency and product quality.

Future Prospects and Industry Trends

Looking ahead, the SMC sewage treatment injection mold industry is poised for growth driven by increasing investments in infrastructure development and environmental regulations. As cities expand and modernize their sewage systems, there is a rising demand for durable and sustainable wastewater treatment solutions. Innovations in SMC technology, coupled with advancements in digital manufacturing and automation, will further elevate the capabilities of sewage treatment injection molds, meeting the evolving needs of the global market.