The decision between an LFT mould (Long Fiber Thermoplastic mould) and an STM mould (Short-fiber Thermoplastic Mould) can be crucial. Each mould type has its unique benefits, and choosing the wrong one could affect production efficiency, cost, and product quality. In this article, we'll guide you through the process of making the right choice based on your production needs, such as product type, production scale, and quality requirements.

Identifying Your Production Needs

The first step in choosing between an LFT mould and an STM mould is to clearly define your production needs. Ask yourself the following questions:

What type of product are you manufacturing? If your product requires high strength and durability, an LFT mould might be the better option, as long fiber-reinforced thermoplastics typically offer greater structural integrity. On the other hand, if your products are less demanding in terms of mechanical properties, an STM mould might suffice.

What is the scale of your production? Large-scale production often calls for moulds that can handle high volumes without significant wear and tear. LFT moulds tend to be more durable and may be a better long-term investment for large production runs, whereas STM moulds might be more cost-effective for smaller batches.

What are your quality requirements? The choice of mould will directly impact the quality of the final product. LFT moulds are known for producing high-quality, structurally sound parts, making them suitable for applications where strength is critical, such as automotive components. In contrast, STM moulds may be better suited for less demanding applications.

Comparing LFT Mould and STM Mould

Now that you've identified your production needs, it's time to compare the two mould types:

*Suitability: LFT moulds are more suitable for products that require high mechanical strength and stiffness, such as automotive parts, sports equipment, and industrial goods. STM moulds, on the other hand, are ideal for products that don't require as much reinforcement, like certain consumer goods or household items.

*Cost: STM moulds generally come at a lower initial cost due to simpler design and material requirements. However, for long-term, high-volume production, LFT moulds may offer better value due to their durability and the quality of the parts they produce.

*Production Efficiency: When it comes to production efficiency, STM moulds typically allow for faster cycle times, making them ideal for products where speed and volume are priorities. LFT moulds, while slower, produce stronger and more reliable products, which could be worth the trade-off in time if your product requires enhanced durability.

Principles for Choosing the Right Mould

When selecting between an LFT mould and an STM mould, follow these key principles:

*Match the mould to your production needs: Ensure the mould you select is suitable for the type of product and volume you're producing. LFT moulds are great for high-strength products, while STM moulds are more appropriate for less demanding applications.

*Consider cost-effectiveness: While LFT moulds may come with a higher upfront cost, they can be more cost-effective over time for large-scale, high-quality production. STM moulds are more affordable initially and work well for smaller production runs.

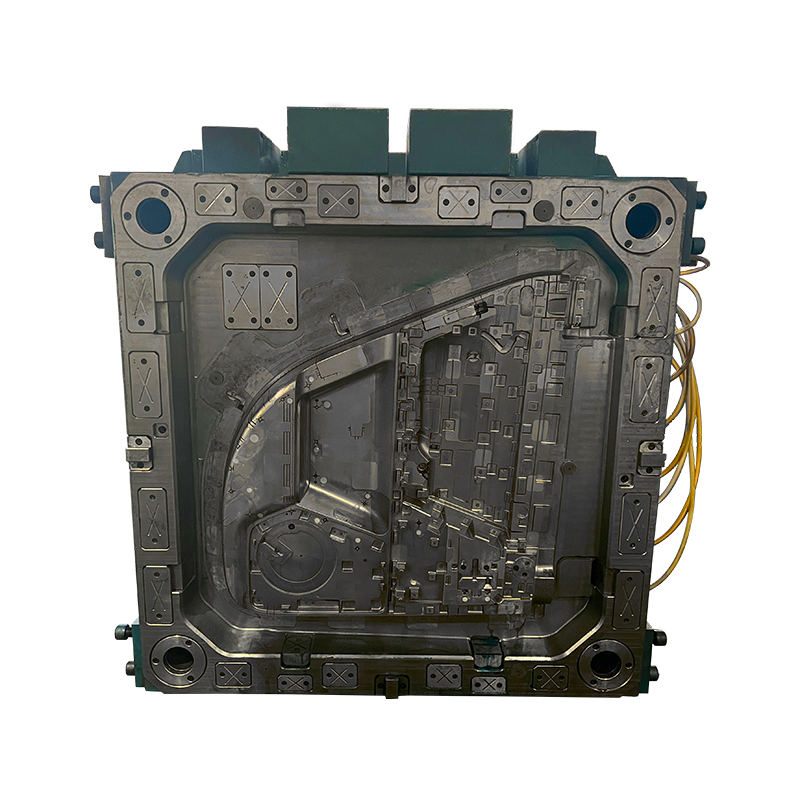

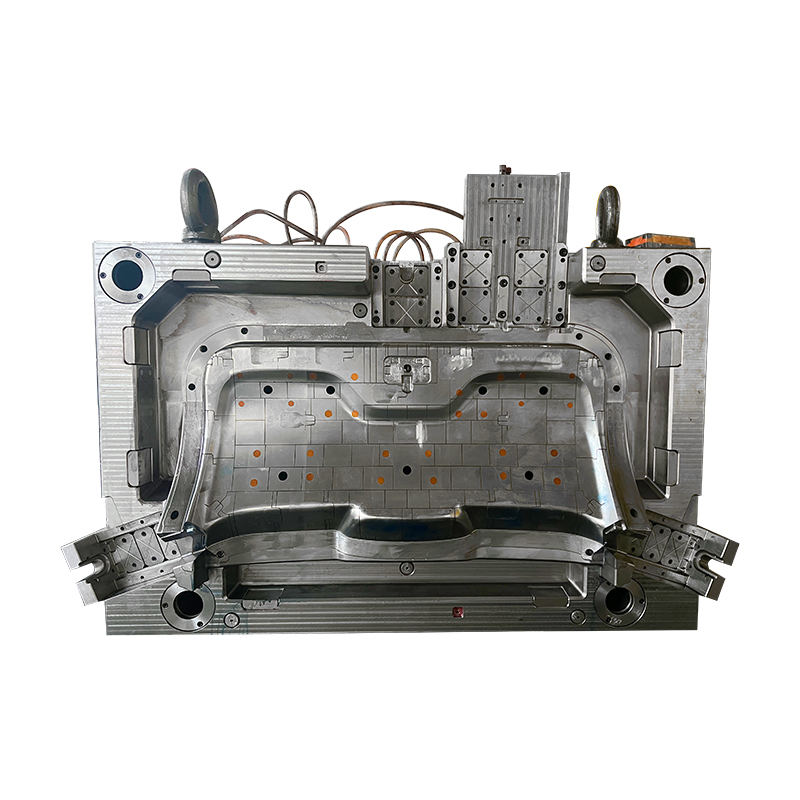

LFT/GMT Automotive Car Body Mould

*Ease of maintenance: Make sure the mould you choose is easy to maintain and has a long lifespan. LFT moulds typically require more maintenance due to the complexity of the process, but they last longer in demanding applications. STM moulds are easier to maintain but may wear out faster in high-volume production.

Evaluating Mould Suppliers

After narrowing down your mould type, you need to assess potential suppliers. A reliable mould supplier will have a proven track record in delivering both LFT moulds and STM moulds to manufacturers. Here are some tips for evaluating suppliers:

*Experience and Expertise: Look for suppliers with significant experience in producing LFT moulds or STM moulds for your specific industry. Ask for references or case studies to validate their claims.

*Service Quality: Choose a supplier who offers comprehensive support, including installation, maintenance, and repair services. Good after-sales service is crucial for ensuring that your moulds remain in peak condition over time.

*Flexibility and Customization: Some suppliers offer customization options that can tailor LFT moulds or STM moulds to your unique production needs. If your project requires a bespoke solution, this can be an essential factor in your decision.

Case Study: Choosing Between LFT Mould and STM Mould

Consider the case of an automotive parts manufacturer who needed to produce lightweight yet strong parts for a new vehicle model. After assessing their production needs, they realized that strength was a key factor, so they opted for LFT moulds. The LFT mould provided the required mechanical properties and durability, ensuring that the parts met safety and performance standards. Another manufacturer, producing consumer electronics casings, chose STM moulds due to the faster cycle times and lower production costs, which were better suited to their needs.

In both cases, the manufacturers made their decisions based on the specific demands of their products and production scales, which is the most effective way to choose between an LFT mould and an STM mould.

Choosing between an LFT mould and an STM mould boils down to understanding your production needs, evaluating the trade-offs between cost, efficiency, and quality, and selecting a reliable supplier. By following the guidelines presented here, you'll be able to make an informed decision that aligns with your production goals.