OEM China SMC circuit breaker and meter box mould Factory

In modern power systems and construction industries, SMC (Sheet Molding Compound) materials are popular for their good performance and cost-effectiveness. As a manufacturer, we focus on the production of SMC meter box mold and SMC circuit breaker box mold. These two products occupy an important position in our production line. This article will conduct an in-depth comparative analysis of these two molds from the manufacturer's perspective.

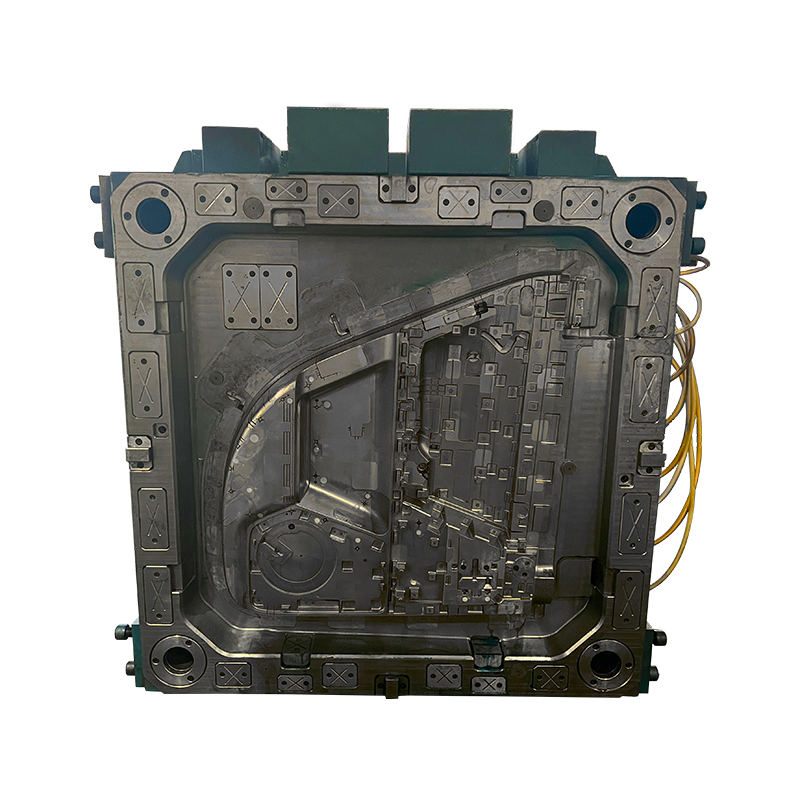

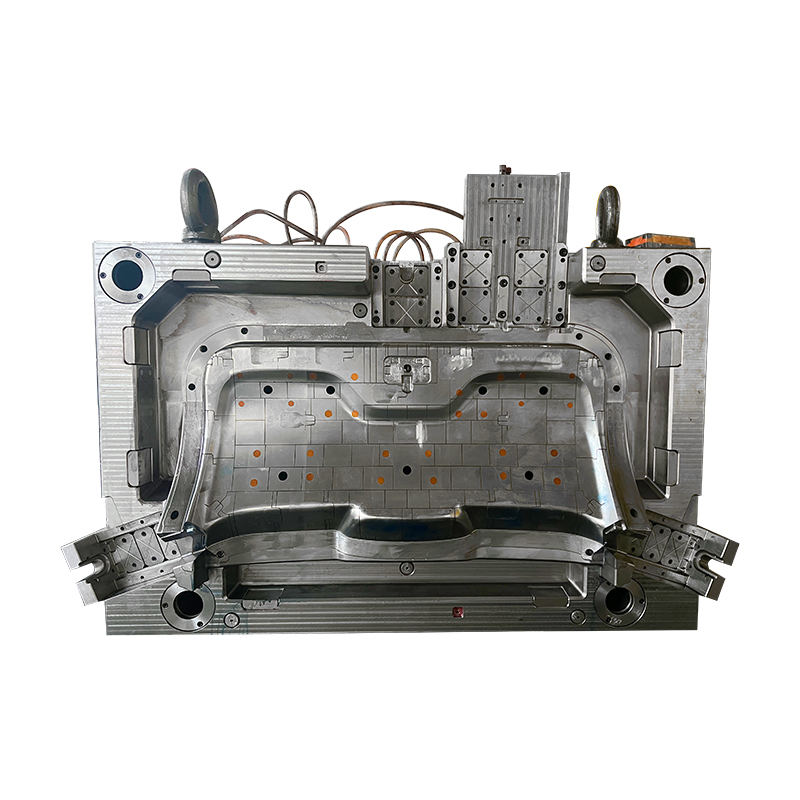

Let’s start with materials and manufacturing processes. SMC material is known for its lightweight, high strength, corrosion resistance and insulation properties, which makes it ideal for manufacturing meter boxes and circuit breaker boxes. Our SMC meter box mold and SMC circuit breaker box mold both use advanced compression molding technology to ensure product consistency and accuracy. During the manufacturing process, we strictly control the quality of raw materials to ensure that every product meets industry standards.

In terms of design, both SMC meter box mold and SMC circuit breaker box mold are carefully designed to meet the needs of different customers. Meter box molds usually need to accommodate meters, terminal blocks and other related equipment, so their internal structure design must take into account the convenience of space utilization and maintenance. The circuit breaker box mold needs to consider the installation method and ease of operation of the circuit breaker. Our team of designers continuously optimizes mold designs to ensure the final product is both beautiful and functional.

Functionally, both SMC meter box mold and SMC circuit breaker box mold are highly adaptable and flexible. The meter box mold can adapt to various sizes and types of electricity meters, while the circuit breaker box mold can adapt to various specifications of circuit breakers. This flexibility allows our molds to meet the needs of different markets and customers.

In terms of durability, both SMC meter box mold and SMC circuit breaker box mold have demonstrated good performance. Due to the weather resistance and chemical resistance of SMC materials, our molds are able to maintain stable performance in various harsh environments. In addition, our molds have a long service life, reducing customers' maintenance costs.

Safety is an important aspect that cannot be ignored in power equipment manufacturing. Our SMC meter box mold and SMC circuit breaker box mold are designed with safety factors in mind. The meter box mold adopts an anti-shock design to ensure the safety of operators. The circuit breaker box mold adopts fire-proof and arc-proof design to prevent accidents.

In terms of production efficiency, both our SMC meter box mold and SMC circuit breaker box mold have high-efficiency production capabilities. Through automated production lines and precise mold design, we are able to quickly produce a large number of high-quality products to meet the large-scale demand of the market.

In terms of cost-effectiveness, both SMC meter box mold and SMC circuit breaker box mold have significant advantages. Since the cost of SMC materials is relatively low and our production process is highly automated, our molds are able to be provided to customers at a lower cost while maintaining the high quality of the product.

In terms of market applications, both SMC meter box mold and SMC circuit breaker box mold have broad application prospects. Meter box molds are widely used in residential, commercial and industrial buildings, while circuit breaker box molds play an important role in power systems, substations and distribution rooms.