SMC (Sheet Molding Compound) meter boxes play a crucial role in housing electrical components and meters, ensuring their protection and longevity in various environments. The manufacturing process of SMC meter box composite molds is a meticulous and critical endeavor that involves precision engineering, material science, and advanced manufacturing techniques.

SMC meter box composite mold manufacturing begins with the selection of suitable materials and the design of the mold itself. SMC is a composite material composed of resins, fillers, and reinforcements such as glass fibers. This combination provides SMC with good mechanical properties, including high strength, impact resistance, and dimensional stability.

Material Selection

The choice of materials for SMC meter box composite molds is critical to ensure the molds can withstand the molding process conditions and produce precise meter box components. Typically, the mold material is made from metals such as steel or aluminum, chosen for their durability, thermal conductivity, and ability to withstand the pressures and temperatures involved in molding SMC.

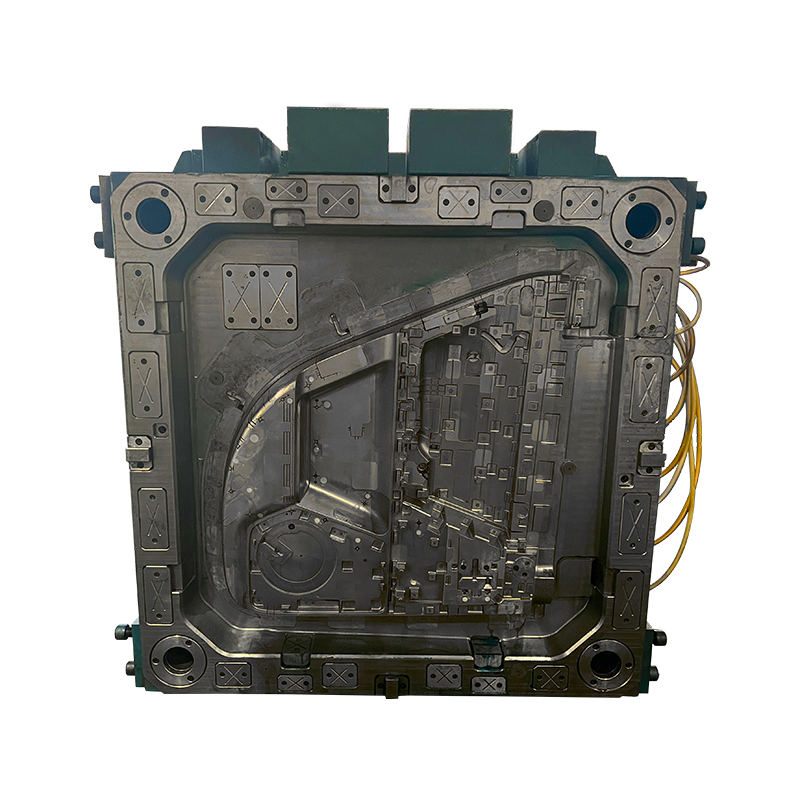

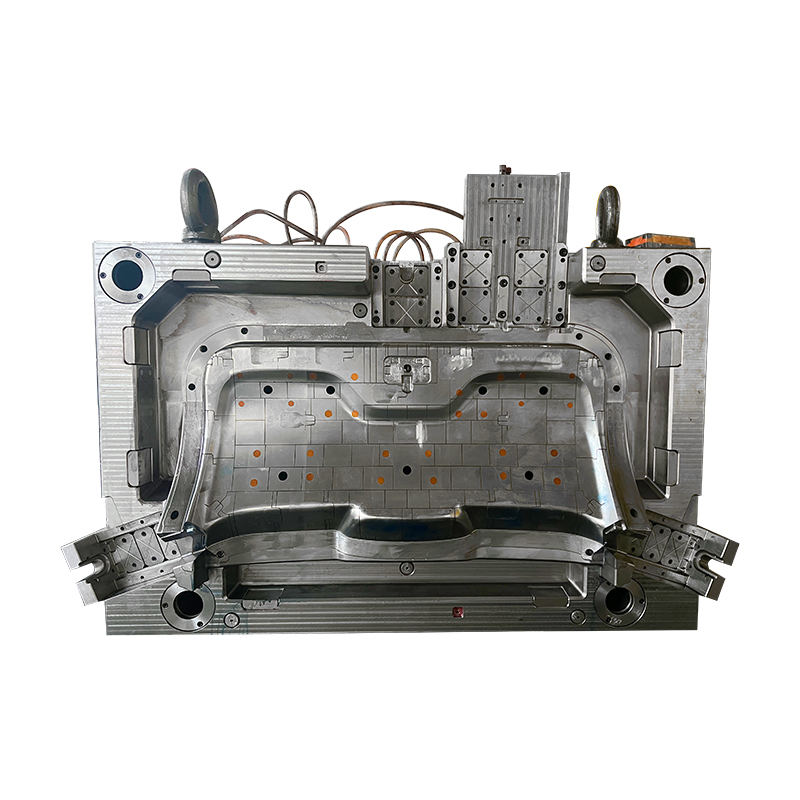

Mold Design

The design of SMC meter box composite molds is a collaborative effort involving mold designers, engineers, and manufacturers. The mold must be meticulously designed to accommodate the specific dimensions and features of the meter box components. Factors such as draft angles, venting, cooling channels, and parting lines are carefully considered to ensure smooth mold release and high-quality part production.

SMC Meter Box Composite Mold Manufacturing Process

The manufacturing process of SMC meter box composite molds can be divided into several key stages:

1. Mold Fabrication

The fabrication of SMC meter box composite molds begins with the preparation of the mold base material, typically steel or aluminum. Precision machining techniques, such as CNC (Computer Numerical Control) milling and EDM (Electrical Discharge Machining), are employed to create the mold cavity according to the approved design specifications. This stage requires high precision to ensure the mold's accuracy and functionality.

2. Surface Treatment

Surface treatment of the mold cavity is crucial to enhance mold durability and prevent corrosion. Techniques such as polishing, coating, and surface hardening may be applied to improve mold release, extend mold life, and maintain part quality during repeated molding cycles.

3. Mold Assembly

Once the mold cavity is prepared and treated, it is assembled with other components such as ejector pins, cooling systems, and gating systems. The assembly process ensures that all elements work seamlessly together to facilitate efficient SMC meter box production.

4. Testing and Validation

Before production commences, SMC meter box composite molds undergo rigorous testing and validation. Mold trials are conducted to verify dimensional accuracy, surface finish, and part quality. Adjustments may be made to optimize mold performance and ensure consistency in part production.

Advantages of SMC Meter Box Composite Mold Manufacturing

The manufacturing of SMC meter box composite molds offers several advantages:

High Precision: SMC molds can achieve intricate designs and precise dimensions, meeting strict tolerance requirements for meter box components.

Durability: The use of robust materials and advanced surface treatments enhances mold longevity and reduces maintenance needs.

Efficiency: Once optimized, SMC meter box composite molds facilitate efficient production cycles, contributing to cost-effectiveness and scalability.

Versatility: SMC molds can accommodate various design complexities and part configurations, adapting to diverse meter box requirements.

Applications of SMC Meter Box Composite Mold Manufacturing

SMC meter box composite mold manufacturing finds application across various industries, including:

Electrical Distribution: Meter boxes for residential, commercial, and industrial applications.

Telecommunications: Enclosures for housing network equipment and cables.

Utilities: Protection and control boxes for water, gas, and energy meters.

The versatility and durability of SMC meter box composite molds make them indispensable in environments requiring reliable and long-lasting housing solutions for sensitive electrical and utility components.