The manufacturing of car bumpers through the plastic injection moulding process is a critical component of automotive production, ensuring both the aesthetic appeal and functional integrity of vehicles. The car bumper plastic injection moulding mould process is a complex sequence of steps that involves careful planning, precision engineering, and rigorous quality control.

Design and Development

The car bumper plastic injection moulding mould process begins with the design and development phase. This stage involves creating detailed blueprints and 3D models of the car bumper, taking into account the vehicle's specifications, safety standards, and aesthetic requirements. Advanced computer-aided design (CAD) software is used to generate accurate models, allowing engineers to simulate the injection moulding process and predict potential issues.

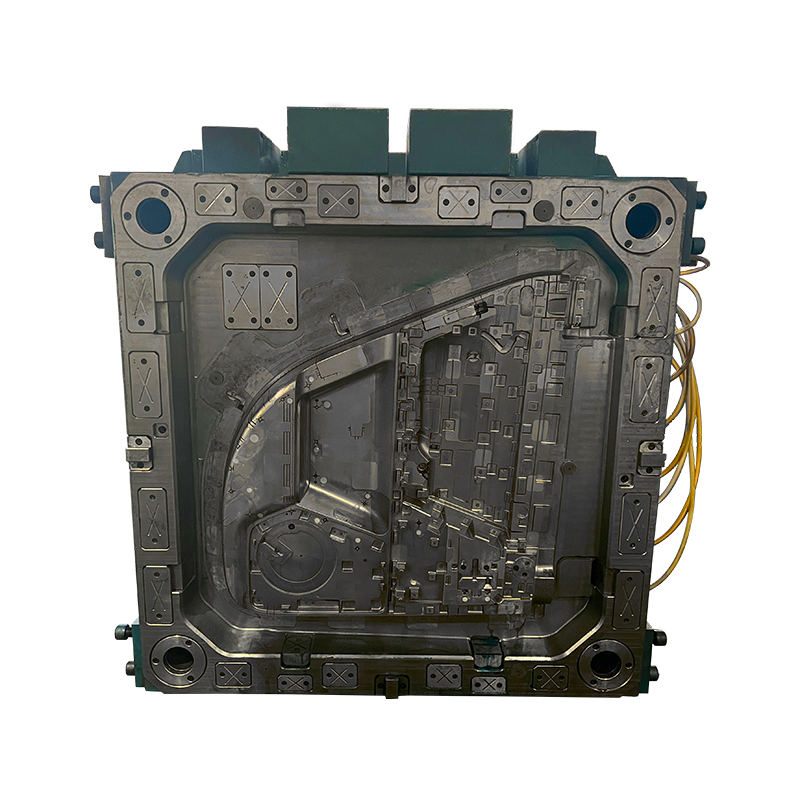

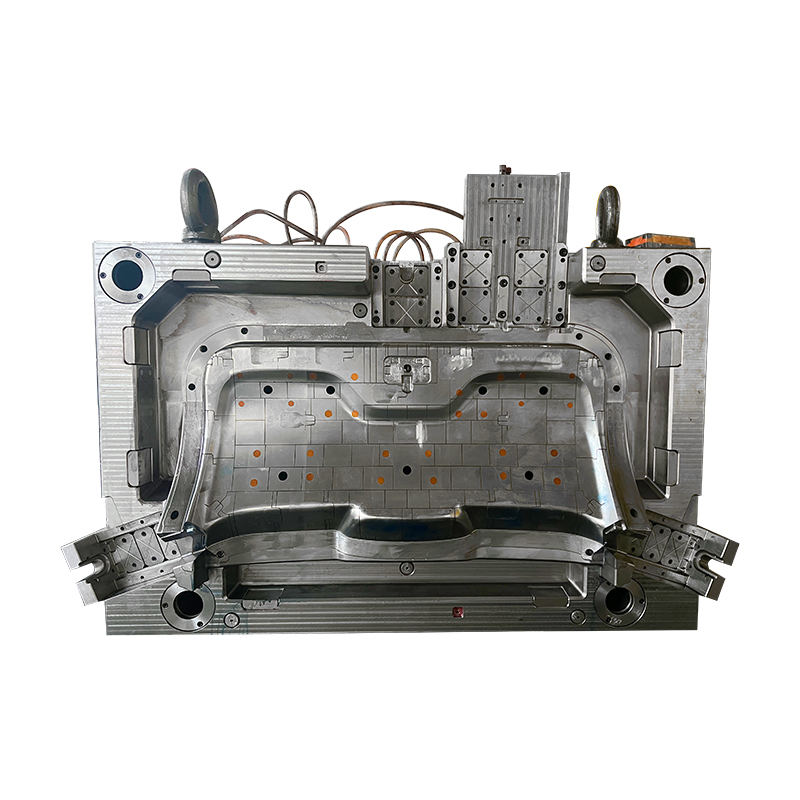

In this phase, the mould design is also finalized. The car bumper plastic injection moulding mould must be meticulously engineered to ensure it can withstand the high pressures and temperatures involved in the injection moulding process. The mould design includes the creation of cavities that shape the molten plastic into the desired bumper form, as well as channels for the plastic flow and cooling systems.

Material Selection

Selecting the appropriate material is crucial for the car bumper plastic injection moulding mould process. Bumpers are typically made from thermoplastic polymers such as polypropylene (PP) or thermoplastic olefins (TPO), which offer a good balance of strength, flexibility, and impact resistance. The chosen material must also be compatible with the injection moulding process and meet the automotive industry's durability and safety standards.

Mould Fabrication

Once the design is complete, the car bumper plastic injection moulding mould is fabricated. This involves machining the mould from high-grade steel or aluminum, materials known for their durability and precision. The mould is crafted with exacting tolerances to ensure the final bumper product is dimensionally accurate and free from defects.

Injection Moulding Process

The core of the car bumper plastic injection moulding mould process is the injection moulding itself. This stage can be broken down into several key steps:

Melting and Injection: The selected plastic material is fed into an injection moulding machine, where it is heated to a molten state. The molten plastic is then injected into the car bumper plastic injection moulding mould under high pressure. The design of the mould ensures that the plastic fills every cavity and void, forming the shape of the bumper.

Cooling: Once the mould is filled, the plastic needs to cool and solidify. Cooling channels within the car bumper plastic injection moulding mould help regulate the temperature and speed up the cooling process. The rate of cooling is carefully controlled to prevent warping or other defects.

Ejection: After the plastic has cooled and solidified, the mould opens, and the newly formed bumper is ejected. The ejection system must be gentle yet effective to avoid damaging the bumper.

Post-Processing

Following ejection, the car bumper undergoes several post-processing steps to ensure it meets quality standards. These steps include trimming any excess material, performing surface finishing, and conducting thorough inspections for defects such as warping, sink marks, or incomplete fills. The bumpers may also be painted or coated to enhance their appearance and provide additional protection.

Quality Control

Quality control is an integral part of the car bumper plastic injection moulding mould process. At various stages, the bumpers are subjected to rigorous testing to ensure they meet the required specifications and performance standards. This includes dimensional checks, material tests, and impact resistance tests. Consistent quality control helps maintain high production standards and reduces the risk of defects in the final product.

Assembly and Integration

After passing quality control, the car bumpers are ready for assembly and integration into vehicles. The bumpers are shipped to automotive assembly plants, where they are fitted onto the vehicles. The precision and quality of the car bumper plastic injection moulding mould process ensure that the bumpers align with the vehicle's body and provide the necessary protection and aesthetic appeal.

Continuous Improvement

The car bumper plastic injection moulding mould process is subject to continuous improvement. Manufacturers regularly review and optimize their processes to enhance efficiency, reduce waste, and improve product quality. Advances in technology, such as automation and real-time monitoring, play a significant role in these improvements, ensuring the injection moulding process remains cutting-edge and competitive.