In the realm of urban infrastructure, the SMC (Sheet Molding Compound) road manhole cover stands as a critical component, providing access to underground utility networks while withstanding the rigors of daily traffic and environmental exposure. The manufacturing process behind these durable covers hinges on advanced technologies, prominently featuring the SMC road manhole cover plastic mold.

Understanding SMC Road Manhole Cover Plastic Mold

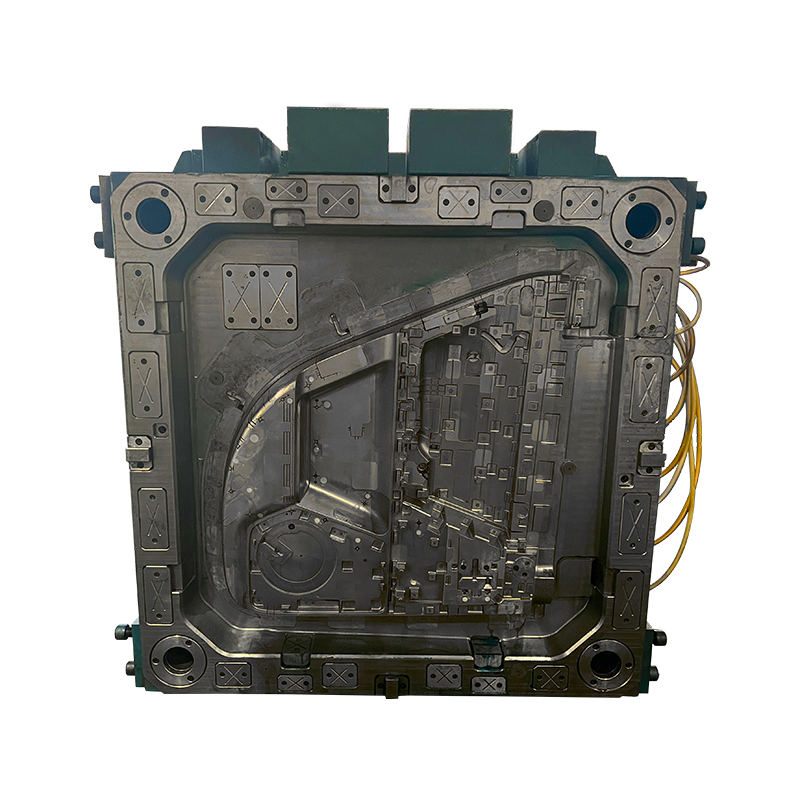

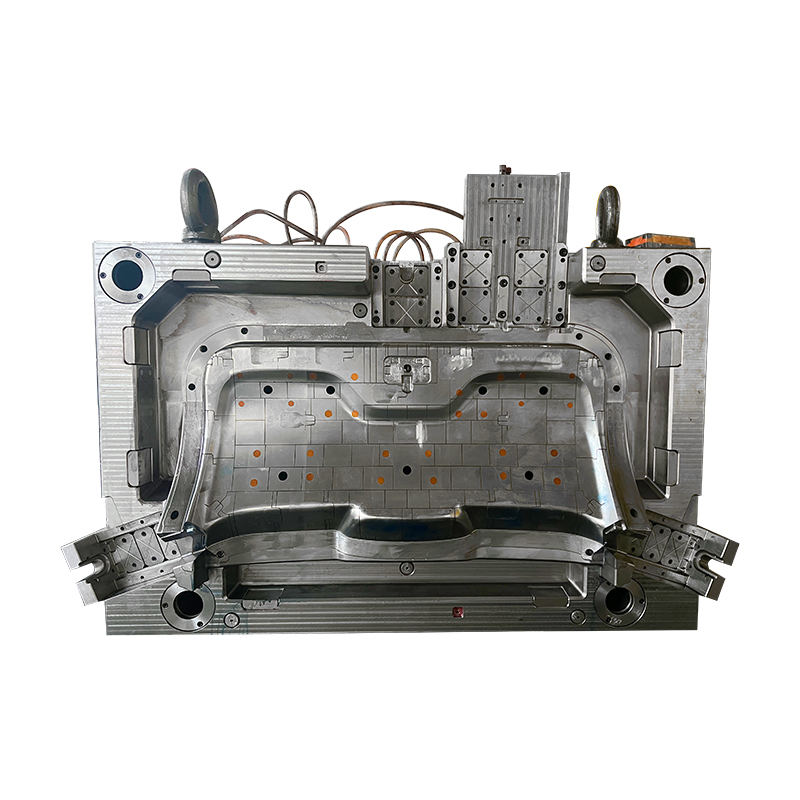

The Wholesale SMC road manhole cover plastic mold is central to the production of durable and corrosion-resistant manhole covers used in urban environments. These molds are engineered from high-strength materials such as steel or aluminum, designed to withstand high pressures and temperatures encountered during the molding process.

Material Composition: SMC is a composite material comprising chopped glass fibers, thermosetting resin, fillers, and additives. This combination yields exceptional mechanical properties, including high strength, impact resistance, and dimensional stability. The SMC material is injected into the mold cavity, where it cures under heat and pressure to form the final manhole cover.

Design and Engineering: The design of the Wholesale SMC road manhole cover plastic mold involves meticulous engineering to ensure precise dimensions and uniform thickness. Features such as load-bearing capacity, anti-slip textures, and drainage channels are integrated into the mold design to meet functional and safety requirements.

Production Process: The production of SMC road manhole covers begins with the preparation of SMC materials, which are fed into the injection molding machine. The SMC material is heated and injected into the mold cavity under controlled conditions. Once cured, the mold opens, and the finished cover is ejected, ready for finishing and installation.

Advantages of SMC Road Manhole Covers: These covers offer numerous advantages over traditional materials such as cast iron or concrete. They are lighter in weight, facilitating easier handling and installation. SMC covers are also resistant to corrosion, chemicals, and temperatures, ensuring long-term durability and minimal maintenance requirements.

Evolution of SMC Road Manhole Cover Plastic Mold

The evolution of Wholesale SMC road manhole cover plastic molds reflects advancements in materials, manufacturing techniques, and design innovations aimed at enhancing product performance and longevity.

Early Developments: Initially, Wholesale SMC road manhole cover molds focused on basic functionalities such as load-bearing capacity and resistance to environmental factors. Early molds were predominantly made from steel due to its robustness and ability to withstand high molding pressures.

Technological Advancements: Over time, technological advancements in mold design and manufacturing processes have refined the production of SMC road manhole covers. Computer-aided design (CAD) and simulation tools optimize mold geometries, ensuring precise molding and consistent part quality.

Material Innovations: Advances in SMC materials have expanded the capabilities of SMC road manhole covers. New formulations offer enhanced properties such as improved impact resistance, UV stability, and color retention, addressing specific performance requirements in diverse environmental conditions.

Customization and Flexibility: Modern Wholesale SMC road manhole cover plastic molds offer flexibility in design and customization. Manufacturers can tailor covers to various load ratings, sizes, shapes, and surface textures to meet municipal specifications and aesthetic preferences.

Sustainability Considerations: The shift towards SMC road manhole covers aligns with sustainability goals, as these covers are recyclable and contribute to reducing carbon footprints compared to traditional materials. Their longevity and resistance to degradation also replacement frequency, further enhancing environmental benefits.

Applications and Industry Impact

Wholesale SMC road manhole cover plastic molds find widespread applications in urban infrastructure projects worldwide:

Municipalities: Used for covering access points to underground utility networks such as water, sewer, and telecommunications systems.

Transportation: Installed on roads, highways, and airports to provide access to utility maintenance and inspection points.

Commercial and Industrial Sites: Utilized in industrial facilities, parking lots, and public spaces to ensure safety, accessibility, and durability under heavy traffic loads.

Conclusion