SMC Water Tank Component Plastic Mold Company plays a crucial role in the manufacturing sector, specializing in the production of molds for various components used in SMC (Sheet Molding Compound) water tanks. These molds are instrumental in shaping the structural and functional elements that comprise SMC water tanks, which are widely utilized for storing water in residential, commercial, and industrial settings.

1. Roof Panel Molds

Roof panels are integral components of SMC water tanks, providing protection from external elements and ensuring structural stability. SMC Water Tank Component Plastic Mold Company designs and manufactures roof panel molds with precision and durability in mind. These molds enable the production of roof panels that are uniform in thickness and geometry, essential for maintaining the integrity of the water tank structure.

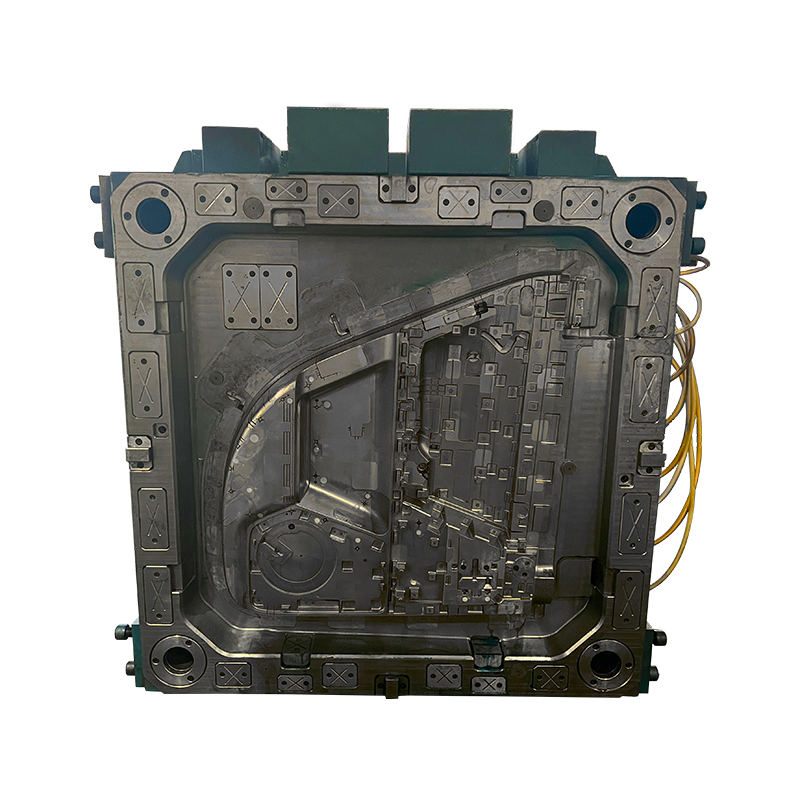

2. Side Panel Molds

Side panels form the vertical walls of SMC water tanks, contributing to their overall capacity and strength. The molds used for manufacturing side panels are designed to accommodate specific dimensions and configurations, ensuring that each panel meets quality standards for durability and leak-proof performance. SMC Water Tank Component Plastic Mold Company employs advanced molding techniques to create side panel molds that facilitate efficient production processes and consistent product quality.

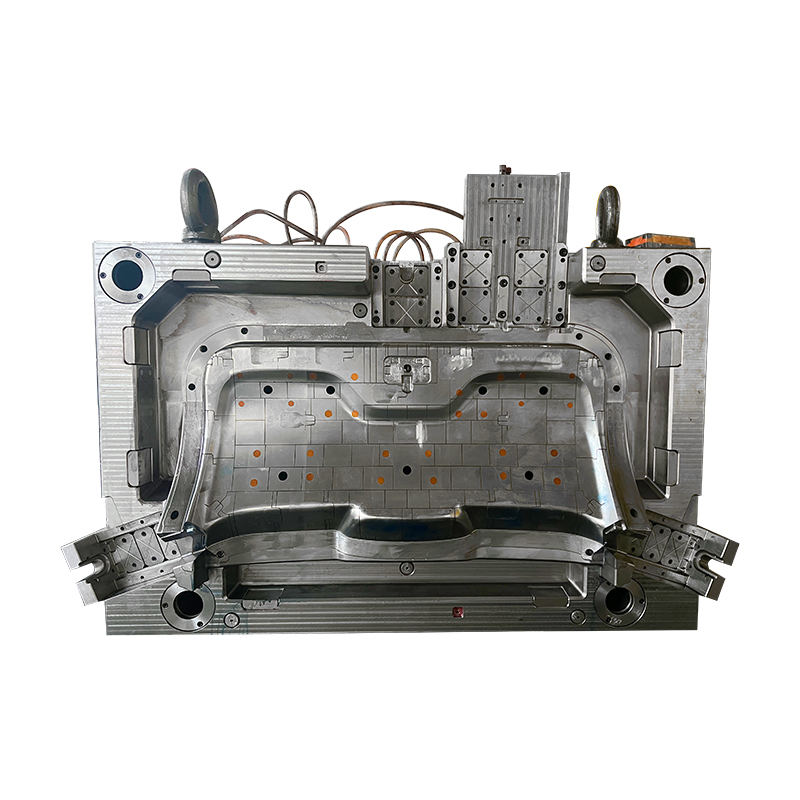

3. Base Molds

The base of an SMC water tank supports its entire structure and must withstand the weight of the stored water. Base molds produced by SMC Water Tank Component Plastic Mold Company are engineered to withstand high pressures during molding and ensure that the resulting bases are robust and dimensionally accurate. These molds play a critical role in manufacturing bases that meet safety standards and operational requirements for water storage systems.

4. Manhole Cover Molds

Manhole covers provide access points for inspection and maintenance of SMC water tanks. SMC Water Tank Component Plastic Mold Company designs manhole cover molds that produce covers with precise dimensions and features, such as locking mechanisms and anti-slip textures. These molds ensure that manhole covers fit securely and remain durable over time, contributing to the longevity and functionality of SMC water tank installations.

5. Flange Molds

Flanges are essential for connecting various components of SMC water tanks, such as panels and pipes, ensuring structural integrity and water-tight seals. SMC Water Tank Component Plastic Mold Company flange molds that enable the production of flanges with accurate dimensions and smooth surfaces. These molds are designed to withstand the molding process's pressures and temperatures, producing flanges that meet industry standards for strength and reliability.

6. Fitting Molds

Fittings, including inlet and outlet fittings, play a crucial role in facilitating the flow of water into and out of SMC water tanks. SMC Water Tank Component Plastic Mold Company produces fitting molds that shape fittings with precise threading and sealing features. These molds ensure that fittings integrate seamlessly with the tank structure, maintaining water integrity and operational efficiency.

7. Ladder Molds

Ladders provide access to the top of SMC water tanks for maintenance purposes. SMC Water Tank Component Plastic Mold Company designs ladder molds that produce durable and secure ladder components. These molds are crafted to create ladders that withstand environmental conditions and ensure safe access to tank operators and maintenance personnel.

8. Reinforcement Molds

Reinforcements enhance the structural strength of SMC water tanks, particularly in areas prone to stress and pressure. SMC Water Tank Component Plastic Mold Company manufactures reinforcement molds that produce components such as ribs and braces. These molds are engineered to create reinforcements that distribute loads evenly across the tank structure, improving overall stability and durability.

9. Divider Panel Molds

Divider panels are used in large SMC water tanks to create compartments for segregating water storage. SMC Water Tank Component Plastic Mold Company designs divider panel molds that produce panels with precise dimensions and smooth surfaces. These molds ensure that divider panels fit securely within the tank, optimizing storage capacity and operational flexibility.