In the world of automotive manufacturing, high-quality automotive parts moulds are indispensable. These moulds are integral to producing the high-precision, high-performance parts that define modern vehicles. From the engines and braking systems to electronic components and body parts, automotive parts moulds ensure that each piece is manufactured with the accuracy and reliability. This article explores why high-quality automotive parts moulds are essential for vehicle production, covering their benefits for precision, cost-efficiency, and overall vehicle quality.

1. Why High-Quality Automotive Parts Moulds Are Essential for Precision and Consistency:

In automotive manufacturing, the precision of every component is critical. High-quality automotive parts moulds ensure that vehicle components meet the strictest specifications, guaranteeing uniformity and quality across every part produced. Without precision in the moulding process, the entire production chain could be compromised. Poorly made moulds can result in inconsistencies, defects, and even safety risks in the final product.

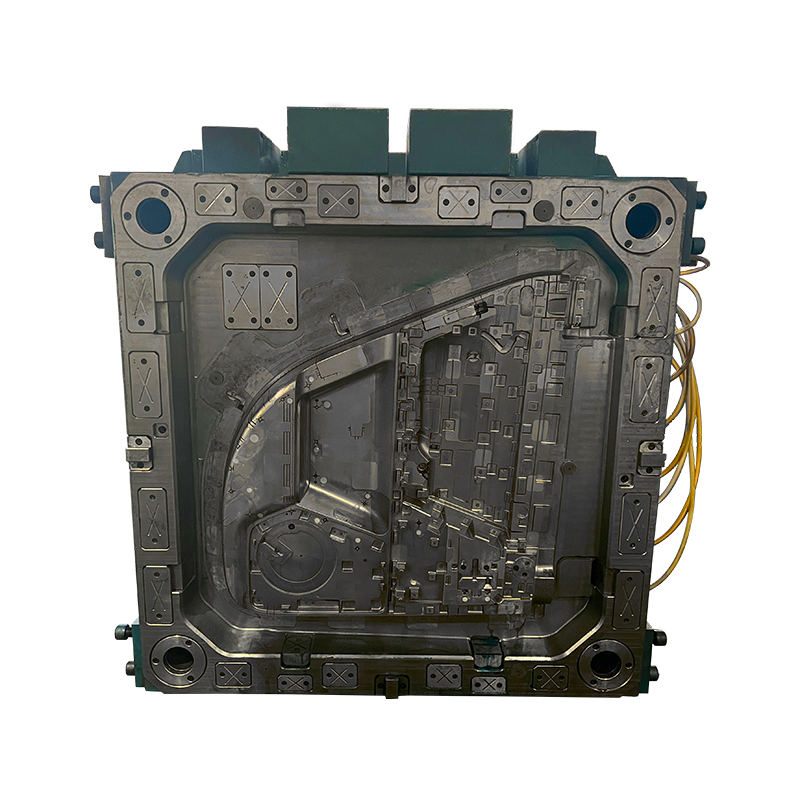

Automotive Hot Runner System Mold

Consistency Across Production Runs: High-quality automotive parts moulds maintain their integrity through many production cycles. This consistency ensures that every part produced is virtually identical, maintaining the same high standards across large production volumes. This is especially important in industries where vehicle safety is paramount.

Minimized Defects: With high-quality moulds, manufacturers experience a lower defect rate, which directly correlates with fewer parts needing to be scrapped. This not only helps to reduce costs but also ensures that each automotive component performs optimally in the final vehicle assembly.

2. Enhancing Manufacturing Efficiency with High-Quality Automotive Parts Moulds:

Automotive manufacturers are always looking for ways to improve efficiency and reduce production costs. The quality of the automotive parts moulds they use plays a pivotal role in achieving these goals.

Faster Production Time: High-quality automotive parts moulds are designed to work seamlessly in fast-paced manufacturing environments. They allow for quicker cycle times, meaning that more parts can be produced in a shorter period without compromising quality. This increases throughput and helps manufacturers meet demand without sacrificing the standard of their final product.

Extended Mould Life: One of the benefits of high-quality automotive parts moulds is their durability. Premium moulds are designed to last longer, which reduces the frequency of mould replacements and associated downtime. This extends the overall lifespan of production equipment, lowering the costs associated with frequent repairs or replacements.

3. Cost Reduction and ROI with High-Quality Automotive Parts Moulds:

While the initial cost of investing in high-quality automotive parts moulds may seem higher, the long-term benefits far outweigh the expense.

Lower Repair and Maintenance Costs: Poor-quality moulds can cause breakdowns, requiring repairs and increasing maintenance costs. However, high-quality automotive parts moulds are built to withstand the pressures of mass production, reducing the likelihood of malfunctions and the need for constant repairs.

Reduced Material Waste: High-quality moulds reduce the risk of defects during production, which results in less material waste. Less scrap material means fewer resources are wasted, lowering production costs and improving profitability.

Increased Profit Margins: By enhancing production efficiency, reducing defects, and minimizing downtime, high-quality automotive parts moulds contribute to overall cost savings. This leads to improved profit margins for manufacturers, making it a smart investment in the long run.

4. The Role of High-Quality Automotive Parts Moulds in Safety and Performance:

The role of high-quality automotive parts moulds extends beyond simply shaping components—they ensure that the vehicle parts produced meet the stringent safety and performance standards required in the automotive industry.

Strength and Durability: Certain automotive parts, such as structural components, braking systems, and engine parts, require exceptional strength and durability. High-quality automotive parts moulds ensure that these critical components have the necessary structural integrity to function safely and effectively under a variety of conditions.

Meeting Regulatory Standards: Vehicles are subject to rigorous safety and quality standards, both at the national and international levels. High-quality automotive parts moulds help manufacturers produce parts that meet or exceed these regulations, ensuring that the final vehicle is compliant with all safety and environmental requirements.

5. How High-Quality Automotive Parts Moulds Contribute to Product Innovation:

As the automotive industry evolves, so do the requirements for moulding technology. With the rise of electric vehicles (EVs), hybrid models, and smart automotive systems, automotive parts moulds are increasingly used to create complex parts that require innovative design and precision engineering.

Support for Complex Designs: As vehicle design becomes more sophisticated, so too does the demand for high-quality automotive parts moulds that can handle complex shapes and intricate features. These moulds enable manufacturers to produce cutting-edge parts for innovative automotive technologies, such as autonomous driving systems, electric drivetrains, and advanced infotainment systems.

Flexibility and Customization: Premium moulds can be tailored to meet specific design needs, ensuring that every component fits perfectly into the final vehicle assembly. This adaptability is essential in a fast-evolving industry, where new materials and technologies frequently shape the design of automotive parts.

6. Choosing the Right High-Quality Automotive Parts Mould Supplier:

To reap the benefits of high-quality automotive parts moulds, it's essential to choose the right supplier. Not all moulds are created equal, and selecting a supplier that provides the standard of products can make a significant difference in the success of an automotive manufacturing operation.

Experience and Expertise: A reputable supplier with extensive experience in the automotive industry can provide insights into the types of moulds for different types of vehicle parts. Their expertise ensures that the moulds they supply will meet your production needs.

Technology and Quality Control: Look for a supplier that employs advanced technology and robust quality control systems. High-quality automotive parts moulds are a result of precise manufacturing techniques, and choosing a supplier who follows practices can guarantee that the moulds they produce are of the quality.

In the competitive world of automotive manufacturing, high-quality automotive parts moulds are an essential investment. They ensure precision, enhance production efficiency, reduce costs, and guarantee the safety and durability of automotive components. As the automotive industry continues to evolve, investing in the right automotive parts moulds is crucial for staying competitive, improving profitability, and producing vehicles that meet the standards of quality and performance. Automotive manufacturers should prioritize the selection of high-quality moulds to stay ahead in an increasingly complex and demanding industry.