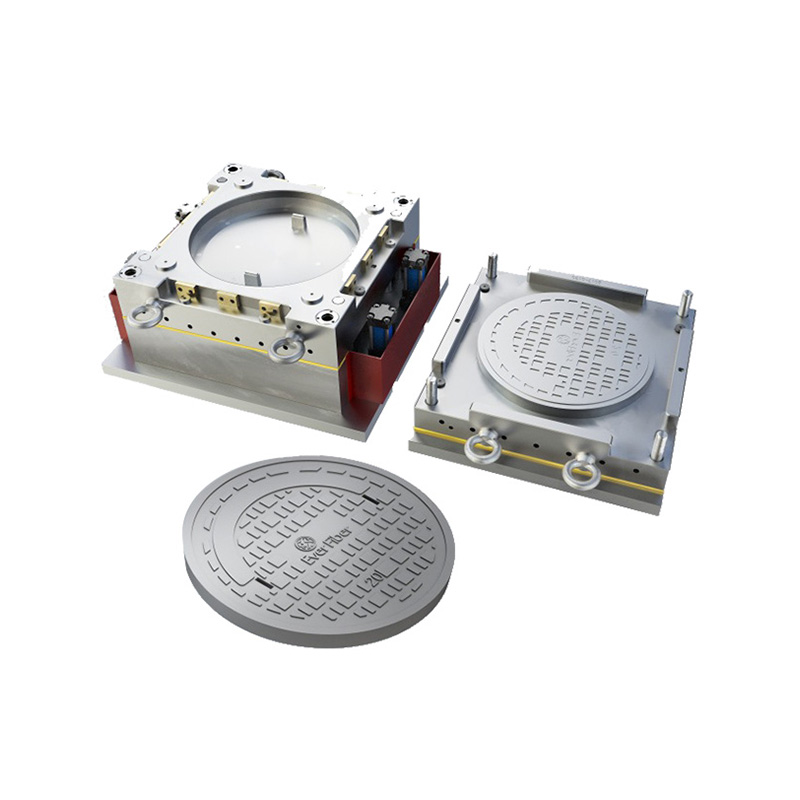

SMC Sewer Fiberglass Manhole Cover Mould

|

Cover Shape |

Round / Rectangle / Square |

|

Cover Load |

A15, B125, C250, D400; according to customer standards requirement |

|

Mould Type |

Compression mould |

|

Mould Steel |

P20 / S50C / S45 |

|

Mould Cavity |

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts |

|

Heating System |

Oil heating / Electrical rods heating |

|

Ejection System |

Hydraulic eject with air assist / hydraulic pins |

|

Mould Cycle |

depends on mould steel, P20 could support around 300 thousand lifespans |

|

Lead Time |

50 days |

Liberal Mould specialises in composite mould and injection mould, we are capable of providing a one-off solution for our customers from mould development, design, and mould making to finished products according to our customer requirements.

The SMC Sewer Fiberglass Manhole Cover Mould represents a advanced solution in the realm of sewer infrastructure. Our company excels in composite mould and injection mould technologies, offering tailored solutions that span the entire process from initial design to the creation of finished products. Our commitment is to deliver high-quality, durable, and efficient moulds that meet the specific requirements of our customers.

1. Advanced Composite Technology

At the core of the SMC Sewer Fiberglass Manhole Cover Mould is the use of Sheet Moulding Compound (SMC), a robust composite material known for its mechanical properties and durability. SMC is a combination of fiberglass and resin, which is molded into a shape and then cured under heat and pressure. This technology ensures that the manhole covers produced are not only strong and resistant to impact but also lightweight and corrosion-resistant.

2. Customized Solutions

Our service is distinguished by our ability to provide a one-off solution tailored to individual customer needs. From the initial concept phase through to the final product, we offer a comprehensive suite of services:

Mould Development: We work closely with our clients to understand their specific requirements, including size, load-bearing capacity, and design preferences. This allows us to develop a mould that goodly aligns with their operational needs.

Design Services: Our experienced design team employs advanced CAD software to create detailed and precise mould designs. This ensures accuracy and efficiency in the manufacturing process.

Mould Making: Utilizing advanced technology and techniques, we produce high-quality moulds that are robust, reliable, and capable of withstanding the rigors of production.

3. Durability and Strength

The SMC Sewer Fiberglass Manhole Cover Mould produces manhole covers that offer good durability. The composite material is engineered to withstand harsh environmental conditions, including extreme temperatures, heavy loads, and chemical exposure. This makes it an ideal choice for sewer systems, which often encounter challenging conditions. Additionally, fiberglass’s inherent properties provide high resistance to corrosion, ensuring a longer service life and reduced maintenance requirements.

4. Lightweight and Easy to Handle

One of the standout benefits of using SMC for manhole covers is its lightweight nature. Compared to traditional materials like concrete or cast iron, fiberglass manhole covers are significantly lighter, which simplifies handling and installation. This can lead to reduced labor costs and faster installation times, contributing to overall project efficiency.

5. Enhanced Safety Features

Safety is a critical consideration in manhole cover design. Our SMC Sewer Fiberglass Manhole Cover Moulds incorporate features designed to enhance safety, such as slip-resistant surfaces and strong load-bearing capabilities. These features help to prevent accidents and ensure that the covers perform reliably under varying load conditions.

6. Cost-Effective Solutions

While the initial investment in SMC technology may be higher than conventional materials, the long-term benefits justify the cost. The durability and reduced maintenance requirements translate into lower total lifecycle costs. Additionally, the efficiency in installation and handling can further contribute to cost savings.

7. Quality Assurance

We pride ourselves on our commitment to quality. Each mould undergoes rigorous testing and quality control procedures to ensure that it meets our high standards and the specifications of our clients. Our quality assurance process ensures that every manhole cover produced is of high quality, offering reliability and performance in the field.