When people think about cars, they often picture sleek designs, powerful engines, or luxurious interiors. However, very few give thought to one of the true heroes behind these vehicles: the injection mold. Without these meticulously crafted molds, car manufacturing as we know it wouldn't be possible. In this article, we'll dive into the vital role injection molds play in car manufacturing, particularly in producing car molds, and reveal the process behind their creation. If you've ever wondered how these unsung heroes shape the automotive industry, you're about to find out.

What Is an Injection Mold?

In simple terms, an injection mold is a tool used in the production of plastic components. In the automotive world, these molds are essential for creating everything from dashboards to bumpers. Without them, it would be impossible to mass-produce the intricate parts that make up the modern car. Injection molds are precise, durable, and capable of producing high-quality, uniform parts at scale.

But what exactly goes into making an injection mold, especially when it comes to the production of car molds? Let’s take a closer look at the manufacturing process.

The Manufacturing Process of Injection Molds

Creating an injection mold is no easy feat. It requires careful planning, cutting-edge technology, and a deep understanding of the final product. Here's a breakdown of the major steps involved in the production process:

1. Design Phase

The first step in producing an injection mold is designing it. Engineers create a 3D model of the part that the mold will be used to produce. This design takes into account every detail of the final product, ensuring that the mold will create precise, high-quality parts. For car mold creation, this phase is critical, as even the slightest error could result in parts that don’t fit properly or don’t meet safety standards.

2. Material Selection

After the design is finalized, the next step is to select the right material for the injection mold. Typically, molds are made from hardened steel or aluminum. Steel molds are more expensive, but they are incredibly durable and can be used to produce hundreds of thousands of parts. Aluminum molds, on the other hand, are less durable but cost less to produce, making them ideal for smaller production runs.

3. Mold Machining

With the design in hand and materials selected, the actual mold is created using high-precision machinery. This involves cutting the steel or aluminum into the desired shape using techniques such as CNC (Computer Numerical Control) machining. The mold must be cut to exact specifications, as even a tiny mistake can affect the entire production process.

4. Testing and Adjustments

Once the mold is made, it undergoes rigorous testing. A sample part is produced using the mold to check for any issues, such as defects or improper dimensions. If any problems are found, adjustments are made to the mold before it can be used for mass production. This step is crucial for ensuring that car molds are perfect, as even the smallest flaw could result in a faulty part.

5. Production

Once the mold has been tested and approved, it can be used in the injection molding process. Plastic is melted and injected into the mold at high pressure, where it takes the shape of the mold cavity. After cooling, the newly formed part is ejected from the mold, ready to be assembled into the final product. For car manufacturers, this process is repeated thousands of times to create the numerous parts needed to assemble a vehicle.

Why Injection Molds Are Essential to Car Manufacturing

Injection molds are, without a doubt, the backbone of the automotive industry. They enable car manufacturers to produce large quantities of high-quality parts efficiently and cost-effectively. From exterior panels to interior components, injection molds are used to create a wide range of car parts that are crucial to the vehicle’s function and appearance.

In addition to their role in producing car molds, injection molds also make it possible to create parts with complex shapes that would be difficult or impossible to produce using other methods. This flexibility allows car designers to push the boundaries of what’s possible, resulting in vehicles that are more innovative and visually appealing.

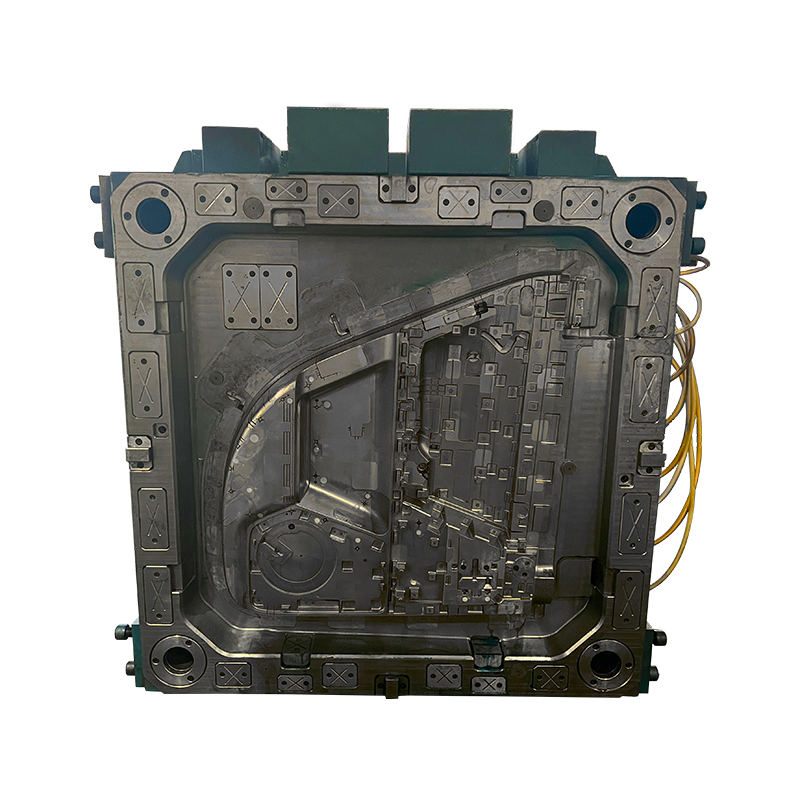

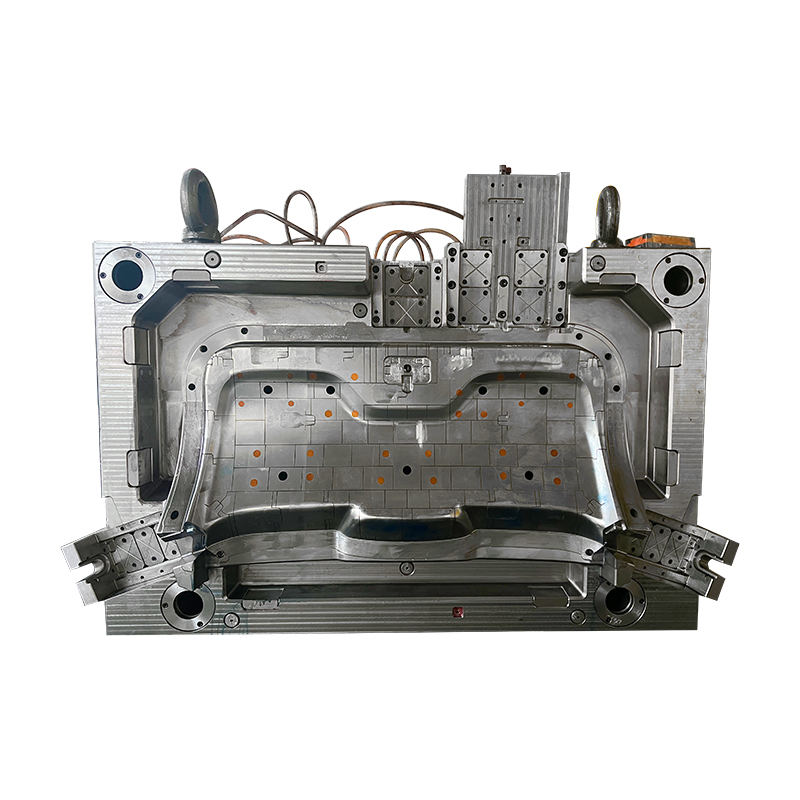

Plastic Injection Auto Spare Parts Mold

The next time you admire a sleek car or marvel at the complexity of its design, remember the unsung heroes behind it—the injection molds. These essential tools are responsible for bringing a designer's vision to life and ensuring that the vehicles we drive are safe, reliable, and beautifully made. While injection molds may work behind the scenes, their impact on car manufacturing is nothing short of heroic.